DITRA-DRAIN is a safe and permanently effective passive capillary bonded drainage mat. For installations in outdoor areas, use thin-bed tile adhesive over a sloped bonded waterproofing assembly such as Schlüter-KERDI.

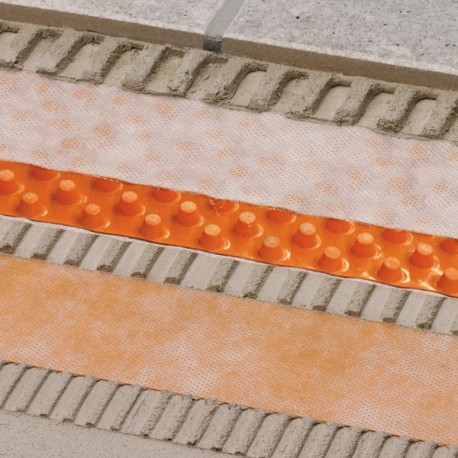

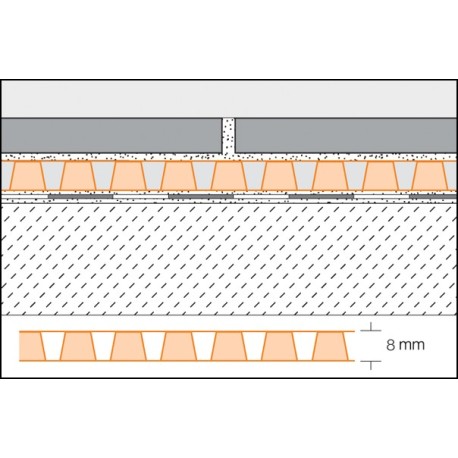

Schlüter-DITRA-DRAIN 8 consists of a dimensionally stable polyethylene sheet with truncated conical studs on one side and a polypropylene filter webbing laminated on both sides. The filter fleece laminated on the underside promotes the bond of the cementitious tile adhesive, which must be applied with a notched trowel (recommended size: 3 x 3 mm or 4 x 4 mm) to the bonded waterproofing. Completely embed DITRA-DRAIN 8 in the adhesive.

Schlüter-DITRA-DRAIN 8 was specifically developed for outdoor applications.

The closed polyethylene membranes DITRA-DRAIN 4 and 8 form an additional protective layer for bonded waterproofing.

Summary of functions

a) Drainage/ventilation

The ventilation allows for fast drying of the thin-bed tile adhesive. The passive capillary drainage effect ensures that water accumulating in the drainage space flows off without pressure and prevents it from seeping back into the covering layer.

b) Uncoupling

Schlüter-DITRA-DRAIN uncouples the covering from the substrate and neutralises stresses between the substrate and the tile covering that result from various deformations. The material also bridge tension cracks from the substrate and prevent them from affecting the tile covering.

Material

Schlüter-DITRA-DRAIN 8 consists of a dimensionally stable polyethylene sheet with truncated conical studs on one side and a polypropylene filter fabric laminated on both sides.

The material of DITRA-DRAIN is dimensionally stable up to a temperature range of -40 C to + +80°C. Its functional and material characteristics are permanently guaranteed. The material is resistant to ageing and non-rotting. Cutting waste is non-hazardous. Polyethylene is not UV-stable in the long term; the product should not be stored in places with prolonged exposure to direct sunlight.

Installation

- Always check that the substrates on which DITRA-DRAIN is to be installed are level, load bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before placing the bonded waterproofing assembly and installing DITRA-DRAIN. The waterproofing layer must have an adequate slope for drainage.

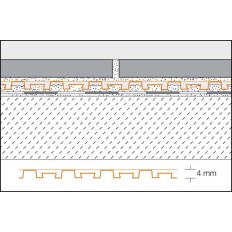

- If using DITRA-DRAIN 4, apply a standard dry set mortar to the substrate on the previously described substrate with a notched trowel (6 x 6 mm). The recommended notching for DITRA-DRAIN 8 is 4 x 4 or 6 x 6 mm. The selection of the tile adhesive to be used with DITRA-DRAIN depends on the corresponding substrate. If using covering materials with a side length exceeding 30 cm, we recommend a water-binding tile adhesive for rapid curing and drying of the mortar.

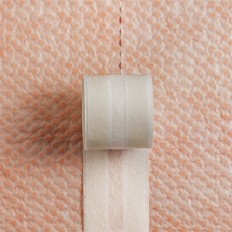

- Embed the DITRA-DRAIN sheets, which must have been cut to size beforehand, in the applied adhesive, and immediately press them in place with a float or roller. If using DITRA-DRAIN 4, check that the inverted truncated pyramid chambers are filled with mortar after the installation. The curing time of the adhesive must be observed. For efficient installation, keep DITRA-DRAIN tightly stretched with light tension when placing it on the substrate. The individual membranes are placed with abutting joints, overlapping the lateral fleece edges. The self-adhesive DITRA-DRAIN-STU joint tape is available for cut edges that have no fleece edge.

- To prevent any damage to the installed DITRA-DRAIN mat or detachment from the substrate, it is recommended to protect the area, e.g. by setting out running boards (particularly in the centre areas used for material transport). Special protective measures may be necessary for outdoor installations, e.g. to shield against direct sunlight or precipitation.

- Tiles or natural stone coverings can be installed immediately after adhering the DITRA-DRAIN mat, using the thin-bed method. All coverings must be solidly embedded in the adhesive.

Maintenance & Care

The cementitious tile adhesive and the covering material used in conjunction with DITRA-DRAIN must be suitable for the respective application area and meet the applicable requirements. In outdoor areas, these materials must be waterproof, frost-proof and weather resistant.

Natural stone and concrete blocks may show discoloration due to different rates of drying.

This covering-specific occurrence cannot be completely ruled out, even if the structural assembly method described in this product data sheet is followed.

We recommend pointing this out to the homeowner when selecting the top covering.

It also must be taken into account that this assembly creates an air layer between the covering and the substrate, which reduces the contact between them. The coverings must be selected appropriately to withstand the anticipated compressive stress. The impact of hard objects must be generally avoided on ceramic coverings. For residential areas and moderate commercial use, tiles should have a minimum size of 5 x 5 cm and a minimum thickness of 5 mm for DITRA-DRAIN 4. In the case of DITRA-DRAIN 8, the minimum tile format is 10 x 10 cm, with a minimum thickness of 8 mm.

Depending on the system, stepping on coverings installed over DITRA-DRAIN with hard shoes or tapping them with a hard object may produce a hollow sound.

Microfine cracks in the joint pattern, which are caused by differences in the expansion coefficient of covering and grout material, cannot be completely ruled out.

The use of quick-curing cementitious tile adhesives that are resistant to weather and frost may be an advantage for certain projects.

Notes on movement joints

Separate Schlüter-DITRA-DRAIN above existing movement joints. Arrange the movement joints in the tile covering as specified by the applicable standards. The dimensions of such sections should not exceed a side length of 3 m in outdoor areas (balconies and terraces).

Smaller sections may be required depending on the substructure and the anticipated temperature fluctuations. In case of connections to upright building structures or wall, tensions must be ruled out by building adequate edge joints. Edge joints and connection joints must be constructed according to the applicable technical regulations and have sufficient dimensions to prevent stress build-up. We recommend using the various profiles of the Schlüter-DILEX family for building movement joints and edge joints.