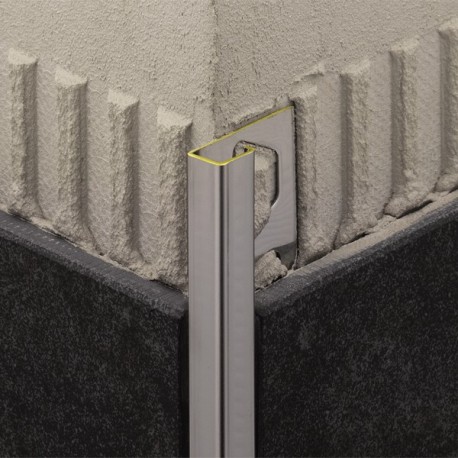

QUADEC-MC is a high-quality chrome-plated brass end profile for exterior corners of ceramic tile-lined walls. The profile surface forms a square outer corner.

QUADEC is a finishing profile for exterior corners of walls covered with ceramic tiles, which also offers good protection for the edges. The profile surface forms a symmetrical square outer corner with ceramic tiles.

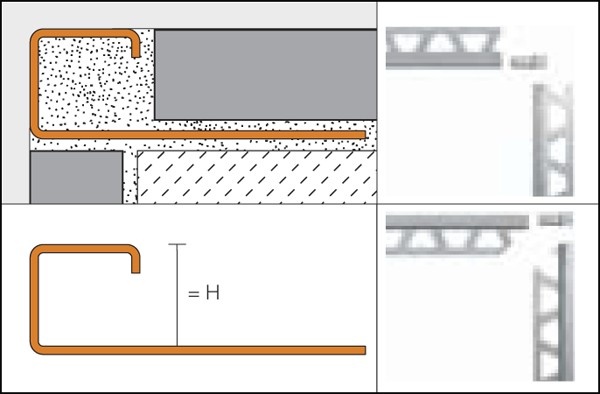

QUADEC in stainless steel is especially indicated for the protection of tile edges, so it is also suitable as a finish profile on floors or as a step on stairs.

Likewise, with QUADEC you can make deliveries, corners or baseboard finishes with other coatings, such as, for example, carpet, parquet, natural stone or epoxy resin flooring. For an easy and aesthetic union of Schlüter QUADEC profiles in interior and exterior corners, there are special pieces, as well as fittings and plugs for some finishes.

Types and finish:

- QUADEC-MC - Chromed brass

Material properties and application fields:

Schlüter QUADEC corner boards are manufactured in a wide variety of materials and finishes. The suitability of the type of material must be checked according to the expected chemical and / or mechanical attacks. Here are some general indications.

Indication:

Due to different production techniques, color differences between the profiles and their angles cannot be excluded.

How to use

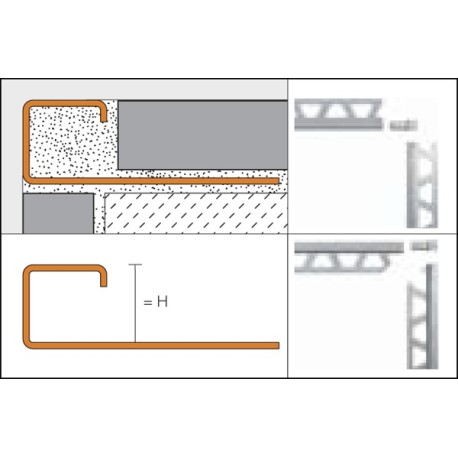

- Choose QUADEC corners according to the thickness of the tiles.

- The cement-glue is applied with a notched trowel over the entire surface where the coating has to be applied. If QUADEC is placed on the outer corner of a wall, the ceramic tiles must be laid on one wall first, and then the cementitious tile is applied to the corner of the second wall.

- QUADEC is placed by pressing the trapezoidal perforated side into the adhesive and the profile is adjusted.

- The perforated side must be completely covered with adhesive and the open chamber of the profile must be filled with cement-glue.

- The tiles are placed by pressing them and adjusting them to the profile level. There should be no gaps on the back of the tiles in the profile areas.

- The tiles are placed next to the profile separator, thus guaranteeing the existence of a uniform 1.5 mm joint. In the case of stainless steel profiles, a joint of approx. 1.5 mm. The joints between the profile and the tiles must be completely filled with grouting mortar.

- Sensitive finishes must be treated with materials and tools, which cannot cause deterioration and scratches. Any remaining grouting mortar or cement-glue must be removed immediately.

- Special parts are supplied for the outer corners.

Maintenance

QUADEC does not require any special maintenance. For sensitive finishes, no abrasive cleaning products should be used.

The oxide layer on brass or aluminum surfaces can be removed by standard polishing products, although it will form again over time. Deterioration of the anodized layers can only be removed by repainting.

Stainless steel profiles obtain a shiny surface using chrome polishing products or the like. Stainless steel finishes exposed to the elements or aggressive substances should be cleaned regularly using non-aggressive cleaning products. Regular cleaning not only maintains the clean appearance of stainless steel but also reduces the risk of corrosion. In no case can cleaning products contain hydrochloric acid or hydrofluoric acid.

Contact with other metals, such as normal steel, should be avoided, as this can lead to contamination with foreign oxide. The same applies to tools such as trowels or steel wool, which are used for the removal of mortar remains. If necessary, Schlüter CLEAN-CP cleaning polish is available.