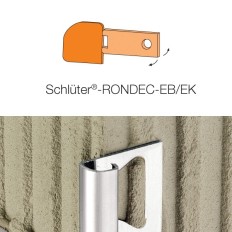

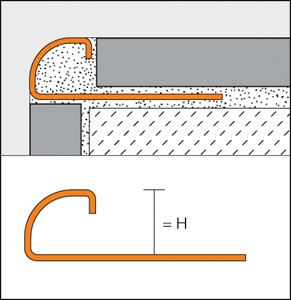

Stainless steel profiles for the corners of walls with ceramic coatings, with different finishes. RONDEC is a finishing and edge protection profile for the external corners of tiled surfaces. It forms a symmetrically rounded outer corner along the surface edge. The integrated joint spacer forms a defined joint cavity with the tile. The profiles are available in different materials, colours and surface finishes to coordinate with tile and grout, fixtures and fittings or to create interesting accents in decorative design.

In addition RONDEC is suitable for transitions, corners or dado coverings with other covering materials e.g. carpet, parquetry, natural stone tiles or epoxy resin finishes. RONDEC also comes with matching internal and external corners for elegant connections.

Material

- AC = Lacquered aluminum

Colour:

- E = Stainless steel

- EP = Polished stainless steel

- EB = Brushed stainless steel

- EV4A = 1.4404-V4A stainless steel (AISI 316L)

Installation

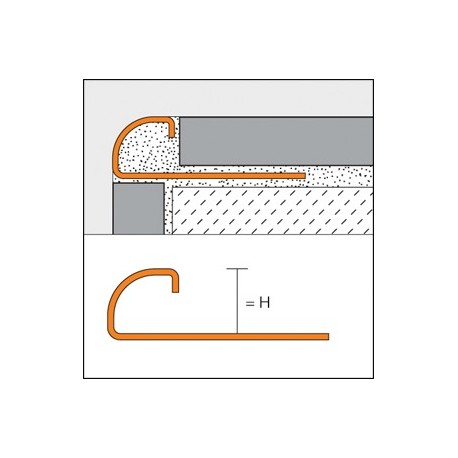

- Select Schlüter RONDEC according to tile thickness.

- Trowel tile adhesive over the area that forms the perimeter of the tiled covering. If Schlüter RONDEC is used at outer wall corners, finish tiling one wall first; then apply tile adhesive to the corner area of the second wall.

- Press the perforated anchoring leg of the Schlüter RONDEC into the tile adhesive and align.

- Trowel additional adhesive over the perforated anchoring leg to ensure full coverage and fill the cavity with tile adhesive.

- Solidly embed adjacent tiles and adjust flush with the profile’s upper edge.

- The tile is set to the lateral joint spacer, which ensures a uniform joint of 1.5 mm. In the case of stainless steel and brass profiles a joint of approximately 1.5 mm is recommended.

- Work on sensitive surfaces with materials and tools that do not cause scratches or damage. Setting materials must be re- moved immediately, especially on aluminium.

- Matching corner pieces are available for internal and external corners.

Maintenance

Schlüter RONDEC requires no special maintenance or care. Abrasive cleaners should not be used on sensitive surfaces. Use conventional polishes to remove the oxidation layer on aluminium; however, oxidation will reoccur. Applying lacquer can repair anodised layers.

Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner. Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid.

Avoid contact with other metals such as steel, which can cause rust. This also includes tools such as trowels or steel wool, i.e. tools used to remove mortar residue. We recommend the use of the stainless steel cleaning polish Schlüter CLEAN-CP.

What is stainless steel?

"Stainless steel" is the collective concept for a group of more than 160 types of stainless steel with different compositions respectively.

This description is based on the creation of a chromium oxide layer on the surface of the stainless steel with a thickness of approx. one thousandth of mm. It is a very thin layer with the capacity to renew itself in case of deterioration, so that as a general rule no rust can appear in this type of steel.

The condition for fulfilling this characteristic is that the protective layer is not damaged for a long time (eg, by contamination with other oxides or certain chemical products, such as hydrochloric acid). These deteriorations can occur especially in areas with chemical attacks, such as e.g. For example, in outdoor areas near the sea or in regions with a high level of industrial air pollution, as well as in the food industry or swimming pools. In these cases we recommend the use of stainless steel grade V4A (material number 1.4404 = AISI 316 L), instead of the conventional grade V2A (material number 1.4301 = AISI 304), which has a higher resistance to oxidation , meeting the highest demands.

The official designation for material No. 1.4301 according to DIN EN 10088 is X5CrNi18-10. The designation for material No. 1.4404 according to DIN EN 10088 is X2CrNiMo17-12-2.