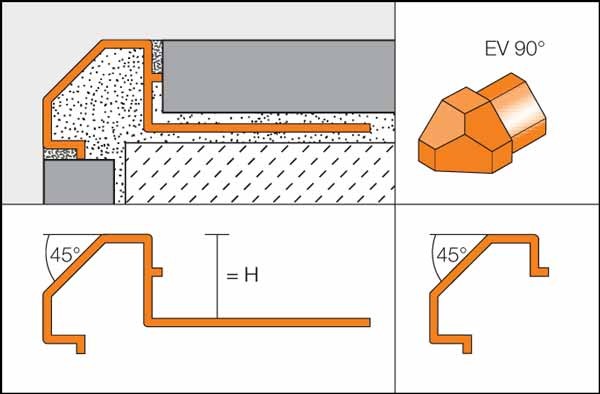

High quality finishing profile of anodised aluminum for exterior wall corners and the edges of tile coverings. The visible area of the profile forms a 45°- degree beveled edge at the exterior corner. The joint spacer defines a joint chamber with the tile.

In addition to the decorative properties of the profile, it effectively protects the edges of tiles from mechanical damage. Schlüter DIADEC is available with or without anchoring leg.

Profiles without anchoring legs can be variably adjusted to any tile thickness from 6 mm with tile adhesive. The product is also suitable for use as a finishing profile if installing tiles over an existing covering to conceal width discrepancies at the wall.

Matching prefabricated parts are available to create simple and elegant connections of Schlüter®-DIADEC profiles to exterior corners.

Schlüter DIADEC is available in the following material varieties:

- AE = Anodised aluminium

- ACG = Polished chrome anodised aluminium

- ACGB = Brushed chrome anodised aluminium

Material properties and areas of application:

In special cases, the suitability of the selected profile type must be verified based on the anticipated chemical, mechanical, and/or other stresses. The information provided below is intended as a general guideline.

Schlüter DIADEC-AE / -ACG / -ACGB (anodised aluminum): The aluminum features an anodised surface layer that retains a uniform appearance during normal use. Visible surfaces should be protected against abrasion. Aluminum is sensitive to alkaline media. Cementitious materials, in conjunction with moisture, become alkaline. Since aluminum is sensitive to alkaline substances, exposure to the alkali (depending on the concentration and duration of exposure) may result in corrosion (aluminum hydroxide formation).

For this reason, remove mortar or grouting material immediately from all visible areas and do not cover freshly installed coverings with foil. In addition, ensure that the profile is solidly embedded in the setting material to prevent water from accumulating in small cavities.

Installation with anchoring leg

- Select Schlüter DIADEC according to the tile thickness.

- Apply tile adhesive to the area where the tile covering will end, using a notched trowel. If Schlüter DIADEC is to be installed in an exterior wall corner, complete the tiling of one wall, then apply tile adhesive in the corner area of the second wall.

- Press the perforated anchoring leg of Schlüter DIADEC securely into the setting material and align the profile.

- Trowel additional setting material over the perforated anchoring leg to ensure full coverage.

- Solidly embed the adjoining tiles and align them flush with the top edge of the profile. The tiles must be fully embedded in the area of the profile.

- The tile is set to the lateral joint spacer, which creates an evenly spaced joint of 1.5 mm. Completely fill the space between the tile and the profile with grout.

- Use suitable materials and tools for the sensitive surfaces to avoid scratches or other damage. Residue of mortar and tile adhesive should be removed immediately. Item no. 554055 – issue 12/16 – Reprints will invalidate this issue.

Installation without anchoring leg

- If Schlüter DIADEC is to be installed in an exterior wall corner, complete the tiling of both walls. Leave a space in the size of the profile width in the area of the exterior wall corner.

- Apply tile adhesive to the back of Schlüter®-DIADEC, place it in the exterior wall corner, and push it in place until the surface is flush with the adjoining tile covering.

- The tile is set to the lateral joint spacer, which creates an evenly spaced joint of 1.5 mm. Completely fill the space between the tile and the profile with grout.

- Use suitable materials and tools for the sensitive surfaces to avoid scratches or other damage. Residue of mortar and tile adhesive should be removed immediately.

Maintenance

Schlüter DIADEC requires no special maintenance or care. Do not use abrasive cleaning agents on the sensitive surfaces. Damage to the anodised surfaces can be restored with paint.