Extruded profile that finishes and protects the edges of tiled coverings, as well as other surfacing materials.

Applications include: (e.g. tile to carpet); dado coverings; edge protection at expansion joints; decorative edging for stairs; as well as a finishing profile for all types of surfaces, such as carpet, parquetry, laminates, natural stone coverings, or cold cured resin coverings.

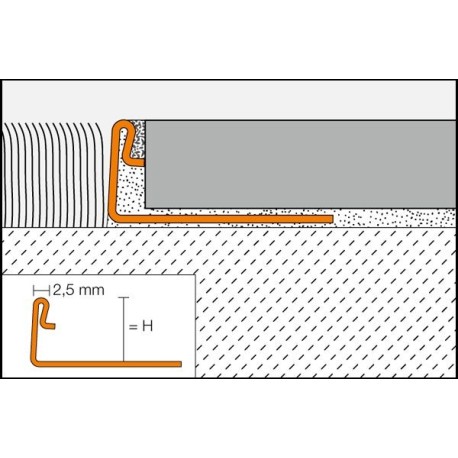

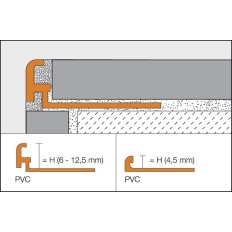

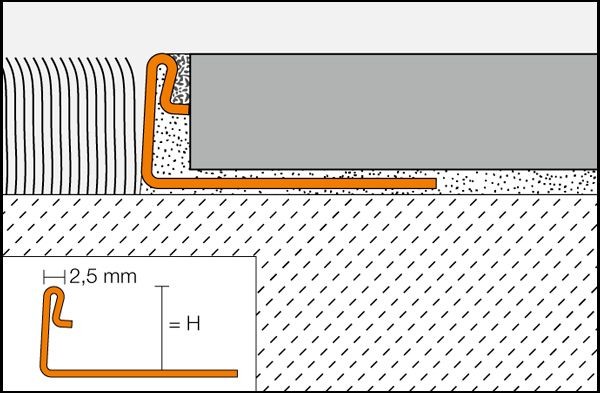

The profile’s unique design combines specific angle positions and material wall thicknesses to transmit point loads into the substrate and surface covering, thus protecting the covering’s edges against damage. The joint spacer, which is integrated in profiles higher than 6 mm, establishes a defined joint cavity between the tile and the profile. The anchoring leg of Schlüter SCHIENE, in all material types, can be punched with a special radius perforation “R” so that the profile can be used to form curves.

Material

Schlüter-SCHIENE is available in the following materials:

- SCHIENE-ES - Stainless steel V2A (AISI 304)

- SCHIENE-ES-EB - Brushed stainless steel V2A (AISI 304

Installation

- Select Schlüter-SCHIENE according to tile thickness.

- Trowel tile adhesive over the area that forms the perimeter of the tiled covering.

- Press the perforated anchoring leg of the SCHIENE into the tile adhesive and align.

- Trowel additional adhesive over the perforated anchoring leg to ensure full coverage.

- Solidly embed the tiles so that the tiled surface is flush with the top of the profile (the profile should not be higher than the tiled surface, but up to approximately 1 mm lower).

- The tile is set to the lateral joint spacer, which ensures a uniform joint of 1.5 mm. With the stainless steel profiles, leave a space of approximately 1.5 mm.

- Fill the joint completely with grout.

Maintenance

SCHIENE requires no special maintenance or care. Do not use abrasive cleaning agents on the sensitive surfaces.

Oxidation films on brass or aluminium may be removed with a common polishing agent; however, they do reoccur. Damaged anodised finishes may only be repaired by recoating. Stainless steel surfaces develop a sheen when treated with a chrome polishing agent etc. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner. Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid.

Avoid contact with other metals such as steel, since this can cause rust. This also includes tools such as trowels or steel wool, i.e. tools used to remove mortar residue. We recommend the use of the stainless steel cleaning polish Schlüter CLEAN-CP.