Novosepara 1 is a made of aluminium or brass profile designed to be installed as a flooring separator. Its sides are striated to im-prove the grip between the profile and the flooring. It can be insta-lled during the tiling work or once it is finished, with high thickness floorings such as terrazzo, marble... It can be polished.

General Features (Aluminium)

- Length: 2,5 ml

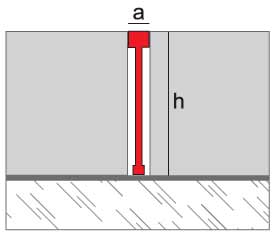

- Size: h: 30 mm (modelo A) / a: 4 mm

- Color: Natural

- Alloy: CU ZN40 AL Pb1 according to the norm NF EN 51-105

- Fire resistance: M0 (UNE 23-727-90)

General Features (Brass)

- Length: 2,5 ml

- Color: Natural

- Alloy: 6063 (AA y ASTM) L-3441 (UNE 38-301-89)

- Size: h: 10/25 (model B), 28’5 mm (model A) / a: 5 mm

- Fire resistance: M0 (UNE 23-727-90)

- Abrasion resistance: High

- Lightfastness: Excellent

- Appearance and color: EN 12373-1

Materials

Aluminium

Novosepara 1 is a profile made by aluminium extrusion.The aluminum is a raw material with excellent chemical and physicomechanical properties. It is light, tough, ductile, malleable and highly durable. It has a great resistance to fire and corrosion.

Brass

Novosepara 1 is a profile made with natural brass. Brass is an alloy of copper and zinc which has mul-tiple industrial applications. It is easy to machine, engrave and melt. It is resistant to corrosion, saline conditions and it is ductile, so it can be transformed in several ways. All Emac®’s brass profiles have been made by extrusion, obtaining so a highly accurate dimensional tolerance which guarantees the optimal appearance and functionality of the profile.

Installation

Novosepara 1 Aluminio is a easy to install profile:

- Do the tiling until the place to install the Novosepara 1

- Apply thin-set mortar and place the profile aligning it with the side of the floor

- Continue with the tiling

- Remove the possible leftover material and let dry

Alternatively, you can install the flooring leaving the gap for the Novosepara 1. Then, spread thin-set mortar or mounting adhesive inside and insert the profile into the gap.

Cleaning and maintenance

Aluminium

The product must be cleaned periodically with a soft cloth. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry it to remove the humidity excess. The persistent dirtiness can be removed by using cleaning approved agents lightly abrasive or a grid covered with polished powder neutral.

Steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is neither recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).

Brass

The Brass, in a natural form, acquires a dull brown color when in contact with aire. To its cleaning there are several products in the market which can be used, even though sometimes can be cleaned with natural acid brushing with lemon and salt. Some of these products are:

- Polishers: Maintain the brass brilliance. These products does not leave any smell in the hands and are easy to use. For its application, moisten a cloth with the product and brush the profile until the superficial discolored layer is removed. Then, use a dry cloth to a perfect finish.

- Shine recoverers: These products recover the shine of pieces made of brass partially oxidized. Given that they can blacken the hands, is necessary to follow the detailed instructions of use. There are versions with high content in Silicon which are more effective than normal.

- Deoxidizing: It recover pieces highly oxidized or oiled. These are very strong and corrosive products whose instructions of use must be strictly followed. It is recommended their use in combination with a fine steel wool to help stripping, being careful not to make much pressure for not scratching material. After using the product, you can use a shine recoverer or polisher to a better finish.

- Varnishes: Are specific products for these metals which cover the material to avoid the loss of appearance of its surface due to oxidizing.