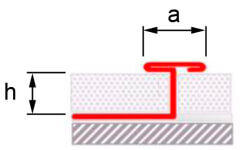

Profile made of AISI-304 Stainless steel, intended to be placed as a trim in joints between floors. Due to its geometry, the face side is overlapped in the floor. This avoids to see the grouted joints below and provides a high decorative value. This profile is available in natural finish high brightness. It is delivered with protective film on its surface, to avoid possible damage in handling and transport.

Dimensions

| Dimensions | ||||

| a (mm) | 12,5 mm | 17 mm | 17 mm | 17 mm |

| h (mm) | 10 mm | 12 mm | 15 mm | 20 mm |

Applications

Novosepara 5 Stainless Steel is a profile intended to be placed as a trim in joints between floors.

Materials

Novosepara 5 Stainless Steel is a profile made of AISI-304 Stainless steel. All material batches are tested with the chemical composition test to determine that they fulfill with the specification of the alloy. Stainless steel used in the Emac® products has been also tested with salt spray test, exceeding 500 hours of exposition without signs of corrosion. Stainless steel is a highly durable and resistent material, with an excellent superficial appearance that does not degrade along the time. The finish available is high brightness. All the finishes are slightly porous and smooth, making easier the hygiene of the installation.

Placement

- Spread a big amount of gripping material on the surface where the pavement will be installed.

- Then,,place the profile and press it to allow the gripping material pass through the mechanized holes on the fixing wing.

- Place a tile on the fixing wing of the profile and press to an optimal contact with the gripping ma-terial.

- Repeat the previous step placing tiles along the profile until the installation is finished. Before cu-ring, tap with a rubber hammer to align the profile with the pavement.

- Finally clean the remaining material and let dry.

Cleaning and maintenance

It’s necessary the immediate cleaning of the material after its installation to avoid that remainings of mortar, concrete or iron particles from wool or tool could cause corrosion.

For outdoor applications, such as facades, the rain is an efficient cleaner. Pay special attention to difficult access areas and be sure you remove all the remainings of dust and the rest of elements. You can do this cleaning once per month.

For indoor applications, you can use water with detergent or liquid soap to remove dirtiness and possible fingerprints marked on the surface. In highly brilliant finishes, you can use a glass cleaner. There are specific cleaners in the markets for stainless steel which clean the material and reduce possible stains. Whenever you clean stainless steel, ensure you rinse it well and dry totally to prevent fogging.

Steel wool or similar products, are not recommended because they could scratch the surface and create pitting corrosion. Pay special attention while using materials containing chlorides, they are not indicated because could oxidize the material. Hydrochloric acid or iron products in a long contact with the material are neither recommended. Do not use cleaners for common steel for the cleaning of stainless steel.