Profile made of aluminum, with T shape, intended to be placed as a trim in joints between floors. Due to its geometry, the face side is overlapped in the floor. Due to its great geometry, it is ideal to be placed during the tiling work or once it is finished. This profile is available in matt silver and matt gold finishes.

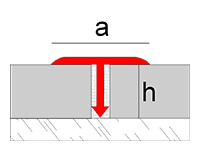

Dimensions

a=15 y 25 mm

h= 7 mm

Technical Features

- Alloy: 6063 (AA and ASTM) / L-3441 (UNE 38-301-89)

- Fire resistance: M0 (UNE 23-727-90)

- Abrasion resistance*: Very good

- Lightfastness*: Excellent

- Appearance and color*: EN 12373-1

*Anodized aluminum

Applications

Novosepara 4 is a profile intended to be placed as a trim in joints between floorings.

Materiales

Novosepara 4 aluminum is a profile made by extrusion of aluminum. The anodizing process improves the corrosion resistance, mechanical resistance and appearance of profiles. It has the quality seal Qualanod, which guarantees the quality of the process and the resulting profiles. This seal regulates several tests: appearance and color, thickness measurements, sealing and impregnation control, abrasion resistance, lightfastness, acetic saline chamber and nitric acid immersion.

The natural finish has no surface treatment so is less resistant to corrosion and scratching. It is not recommended installing natural finishes without the application of an additional protection.

Installation

- Spread a big amount of thin-set mortar on the surface to be tiled.

- Do the tiling and leave the gap to install Novosepara 4.

- Fill the gap with adhesive and insert the profile until it is flush to the floor.

- Finally, clean the leftover material and let dry.

Cleaning and maintenance

The profiles should be cleaned periodically with a soft cloth. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry to remove excess moisture.

In all cases the steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is not recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).