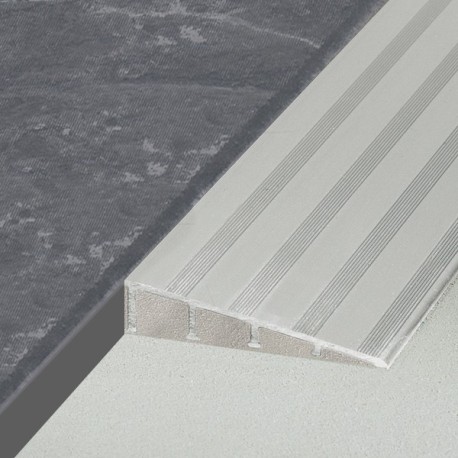

RENO-RAMP-K is a Ramp profile for pavements transition without fixing wing with a slope around 8º that is placed between an existing support and the covering to adjust the height.

Transition profiles for a stepless transition between floor coverings of different heights, for example for the transition from tiles to carpeting. In addition, it protects the edge of adjacent coverings. The integrated joint spacer forms a defined joint cavity with the tile.

Schlüter®-RENO-RAMP is the preferred solution for areas exposed to heavy vehicular traffic. The shallow angle (approximately 10º) of the sloped transition edge ensures the profile is easy to use with forklifts and platform trucks. RENO-RAMP is also suited to create stepless transitions in areas that must comply with disabled access requirements.

Material

The transition profile RENO-RAMP-K is available in the following material version:

- AE = Anodised aluminium

Installation

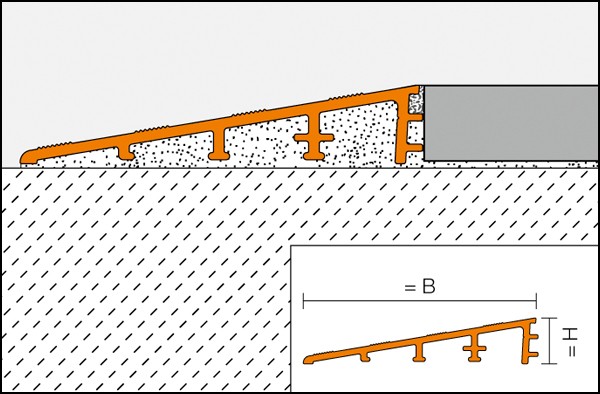

- Select Schlüter RENO RAMP according to tile thickness.

- Fill the cavity beneath the sloped section of the profile with tile adhesive.

- Trowel tile adhesive over the area that forms the perimeter of the tiled covering.

- Press the perforated anchoring leg of the Schlüter RENO RAMP into the tile adhesive and align.

- Trowel additional adhesive over the perfo- rated anchoring leg to ensure full coverage.

- Solidly embed the tiles so that the tiled surface is flush with the top of the profile (the profile should not be higher than the tiled surface, but up to approximately 1 mm lower). The tiles must be fully embedded in the area of the profile.

- The tile is set to the lateral joint spacer, which ensures a uniform joint of 1.5 mm. With the stainless steel profiles, leave a space of approximately 1.5 mm.

- Fill the joint completely with grout.

Maintenance

RAMP-K require no special maintenance or care. Oxidation films on brass or aluminium may be removed with a common polishing agent; however, they do reoccur. Damaged anodised finishes may only be repaired by recoating.

Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner. Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid.

Avoid contact with other metals such as steel, since this can cause rust. This also includes tools such as trowels or steel wool, i.e. tools used to remove mortar residue. We recommend the use of the stainless steel cleaning polish Schlüter CLEAN-CP.