During the setting process, concrete loses moisture and reduces its volume, which generates internal stresses that lead to cracking of the surface. The aim of this range of profiles is to prevent uncontrolled cracking by channelling the crack formation along the profile.

The installation of these profiles also serves as a rule-master and avoids subsequent cutting and sealing work, thus saving costs.

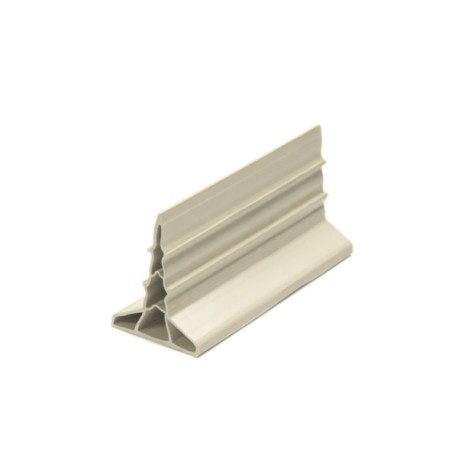

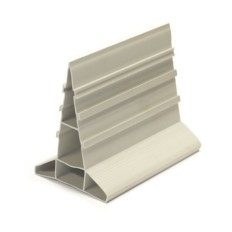

Shrink joint profile made of extruded PVC. By installing this profile, a weak point is created in the slab or floor slab that ensures that the crack created by the shrinkage of the concrete is directed, thus avoiding uncontrolled and unsightly breaks in the surface.

It controls the expansion and retraction of the concrete in slabs up to 24 cm thick, acting as a screed and formwork at the same time. It is easy to install, adhering perfectly to the substrate. Its installation avoids traditional cutting and sealing work.

Its installation avoids the accumulation of dirt in the joints and improves the traditional finish. Because the profile remains embedded in the concrete, it does not suffer degradation over time and is not visible in the paving.

These hollow PVC expansion joints absorb the expansion of the concrete. Its side walls have 2 grooves so that when the concrete expands, the joint follows the movement.

Its wide base gives it perfect stability. The apex of the screed is rigid so that it serves as a guide-slide when the vibrating screed is passed.

The trowelling of these screeds with the screed is normal as well as the polishing on a surface thickness of 2 to 3 millimetres. The screeds are laid in squares within the concrete of the screed.

Its hollow profile can also be used as a cable sleeve or conduit.

Uses: Floor screeds in industrial buildings, platforms, car parks, etc.

Measurements: 40 mm high x 27 mm base.

LAYING

Place a few small trowels of concrete along the length of the joint spaced about 60 - 80 cm apart for a 5 ml. screed in model 80 (7 trowels). At the ends, place the trowels 20 to 25 cm from the ends of the screeds.

Place the level on these points. Place the joints and back them with a little mortar up to half the distance between the 2 grooves at the most. Check alignment with the bead.

Boxes of 60 bars 2.5 m long, 150 metres. Measurements 40 mm high x 27 mm base.

JOINING AND INTERSECTION

To join 2 rulers one after the other, place an iron rod in the upper gap between the rulers.

The ruler is sawed perpendicularly at both ends at an angle of 20º. This joint will pass over the side joints and the vertices will touch at the desired level.

It is advisable to lay vibrated concrete at the intersections and leave the joint clean when trowelling.