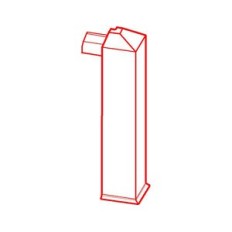

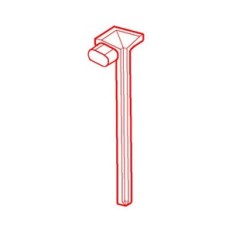

Cover skirting board or baseboard in aluminum to overlap with a simple and modern, elegant and decorative design. Aluminum profiles that can be easily placed without the need for work on a pre-existing skirting board (free demolition!), Saving installation time in renovations and thus improving the prices of its reform. For installation on the wall without prior skirting, we recommend the use of accessory mounting plugs that support the profile and facilitate the perfect fastening.

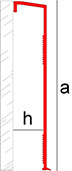

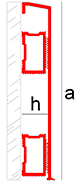

Dimensions

| Model | a | h | Long |

| 80 | 80 mm | 13,8 mm | 2,50 ml |

| 120 | 120 mm | 23,8 mm | 2,50 ml |

Materials

Profile made by extrusion of aluminum. The matte silver and matte bronze finishes have been anodized, mainly improving through this process their resistance to corrosion, mechanical resistance and appearance. The anodizing carried out has the Qualanod quality seal, which guarantees the quality of the process and the resulting profiles. This seal regulates appearance and color tests, thickness measurements, sealing and impregnation control, resistance to abrasion, light fastness, acetic salt chamber and nitric acid immersion.

The off-white finish has been lacquered, obtaining a homogeneous and high-quality surface. The lacquer has the Qualicoat quality seal, which guarantees the quality of the process and of the final products.

Aluminum is a material with excellent chemical and physical-mechanical properties. It is light, tough, ductile, malleable and highly durable.

The complementary pieces are made in Zamak. Zamak is a non-ferrous Zinc alloy with Aluminum, Magnesium and Copper (UNE EN 1774). It is tenacious, has high hardness, great mechanical resistance and excellent plastic deformability. The surface finish applied to them protects them and is similar to Novorodapie Rehabit finishes.

Installation

On prior skirting

- Clean the surface for the placement of the Novorodapie Rehabit.

- Join the add-ons to the Novorodapie Rehabit. This previous step will facilitate the subsequent attachment of the set to the wall.

- Thirdly, apply the adhesive material to the internal surface of the Novorodapie Rehabit so that the contact between the new skirting board and the previous skirting board is ensured. You can use a Fischer Express Sealant / Express Adhesive type or the like.

- Then carefully place the Novorodapie on the previous skirting and press gently.

- Clean off excess material and allow to dry. After drying remove the protective film.

Without prior skirting

- Clean the surface for the placement of the Novorodapie Rehabit.

- Attach the accessories to the Novorodapie Rehabit, including the installation blocks. This previous step will facilitate the subsequent attachment of the set to the wall.

- Thirdly, apply adhesive material to the surface of the placement plugs in the rear area. You can use a Fischer Express Sealant / Express Adhesive type or the like.

- Then carefully place the Novorodapie on the wall, making sure that the installation plugs make contact with it.

- Clean off excess material and allow to dry. After drying remove the protective film.

* If you are going to paint the face, keep the film until you have finished with the operation

Cleaning and maintenance

Cleaning should be done periodically with a soft cloth. If you choose to use a neutral cleaning liquid, it must be rinsed with cold water and dried to remove excess moisture. Stubborn soiling can be removed with mildly abrasive, suitable cleaning agents or a screen coated with neutral polishing powder. If you apply a preservative, in addition to leaving a thin layer of water repellent, keep in mind that it should not be yellow, attract dust or dirt, or have iridescent effects.

The use of steel wool, abrasive or pickling products as well as strong acids (hydrochloric and perchloric), strong bases (caustic soda or ammonia) or carbonated solutions is contraindicated. Citric acid should also not be used as it dissolves the protective oxide layer on the aluminum surface. Waxes, petroleum jelly, lanolin or the like are not suitable. Haloalkane solvents (hydrofluoroethers or chlorinated solvents) and setting accelerators containing chlorides should be avoided (use non-chloride accelerators).