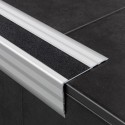

Profile designed to be placed as a stair nosing. Its striated face side and the non-slip strip, help to fulfill the DB-SUA from the CTE, as it improves the value of slip resistance of the flooring where is installed. Novopeldaño Safety is ideal for public areas such as airports, hospitals, hotels... Its ease of installation, without work, makes it specially suitable for reform and rehabilitation works. It fulfills with the DIN51130 requirements.

The non-slip strip of Novopeldaño Safety has a non-slip value certified as R13 according to the DIN 51130 standard. The contrast between the strip and the aluminum profile helps to make it DDA compliant.

Novopeldaño Safety offers maximum functionality in a beatiful profile easy integrable in any environment.

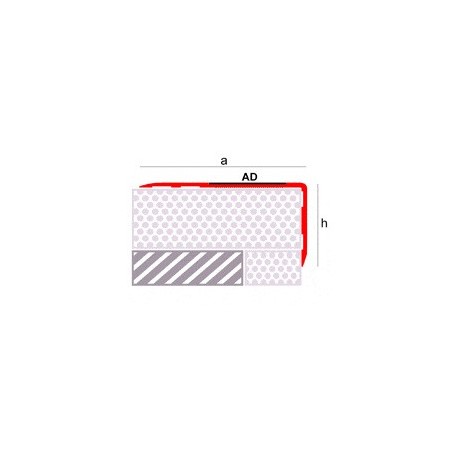

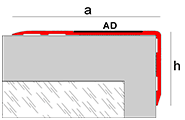

Dimensions

- a: 65 mm

- AD: 30 mm

- h: 40 mm

- Length: 2,50 ml

Technical Features and tests

- Alloy: 6063 / L-3441 - AA y ASTM / UNE 38-301-89

- Fire resistance: M0 / UNE 23-727-90

- Abrasion resistance: Very good

- Lightfastness: Excellent

- Appearance and color: EN 12373-1

- Working temperature(*): - 30ºC / +70ºC

- Water resistance(*): 10 months

- Chemical resistance(*): 8 months

- Motor oil resistance(*): Excellent

- Sliding resistance (*): R13 / DIN51130

(*) Non-slip strip features

Materials

Aluminum

The base of Novopeldaño Safety is a profile made by extrusion of aluminum. These profiles have been anodized, improving through this process their corrosion and mechanical resistance and their appearance.. The anodized applied, has the quality seal “Qualanod” which guarantees the quality of the process and the resulting profiles. This seal regulates several tests: appearance and color, thickness measurements, sealing and impregnation control, abrasion resistance, lightfastness, acetic saline chamber and nitric acid immersion

Aluminum is a material with excellent chemical, physical and mechanical properties. It is lightweight, tough, ductile, malleable and highly durable.

Non-slip strip

The non-slip strip of Novopeldaño Safety is made of aluminum oxide in a 0,1 mm. PVC carrier. It stands well outdoors, resists motor oil and water and has a certified slip resistance R13 (according to DIN51130). This non-slip strip is DDA compliant.

Installation

- Clean the surfaces to be joined to guarantee a perfect adhesion.

- Spread a big amount of adhesive type MS Sealing/Express from Fischer or similar on the rear of Novopeldaño Lúmina.

- Place the profile on the desired surface and push it carefully.

- Finally, let the adhesive dry.

You can also use adhesive mounting tapes or similar.

Cleaning and maintenance

Novopeldaño Safety is resistant to detegents and water. The product must be cleaned periodically with a soft cloth. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry it to remove the humidity excess. The persistent dirtiness can be removed by using cleaning approved agents lightly abrasive or a grid covered with polished powder neutral. If a preserving agent is applied, as well as keep a very thin layer of water repellent, note that it can’t be yellow,attract dust or dirt or have iridescent effects.

Steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is neither recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).