Schlüter TREP-E are non-slip stainless steel rung profiles or stair nosing for staircases for creating secure and decorative rungs. It can be applied on ceramic tile or natural stone steps, as well as with thin coatings from a thickness of 2 mm. It is especially indicated for stairs with high pedestrian traffic, such as p. eg, in offices or public buildings.

The Schlüter TREP-E stair edge protectors protect the edges of the steps and offer a high degree of safety due to their non-slip relief (BIA Test Certificate, Group R 10 V6) and good optical perception. Plugs for the side trim are available as an accessory.

Schlüter TREP-EK is a variant without a locking wing that must be glued to the step. This profile is suitable for subsequent installation on steps with deteriorated edges to avoid replacing damaged tiles.

The Schlüter TREP-EFK rung profiles are an especially non-slip stainless steel profile for safe and attractive rung construction. It can be placed with mounting adhesive on a planned recess or directly on the step.

Material

Schlüter TREP-E is available in the following finishes:

E = Stainless steel

- V2A Material No. 1.4301 = AISI 304

- V4A Material No. 1.4404 = AISI 316L

Schlüter TREP-EK is available in the following finish:

E = Stainless steel

- V2A Material No. 1.4301 = AISI 304

Schlüter TREP-EFK is available in the following finish:

E = Stainless steel

- V4A Material No. 1.4404 = AISI 316L

Properties and fields of application:

In certain cases, the suitability of the type of material must be checked according to the expected chemical or mechanical damage.

The use of Schlüter TREP-E is especially indicated for applications with high mechanical and chemical stresses, such as e.g. eg, in areas where aggressive cleaning products are used. Depending on the expected chemical attacks, you can choose between stainless steel grades 1.4301-V2A (AISI 304) or 1.4404-V4A (AISI 316L). For areas with special aggressions, eg in swimming pools (fresh water), we recommend the use of 1.4404-V4A stainless steel (AISI 316L). Stainless steel does not resist all chemical attacks such as hydrochloric acid, hydrofluoric acid and concentrations of salts. Pay attention in case of saltwater pools (sea water). Special attacks must be checked before the profiles are installed.

How to use

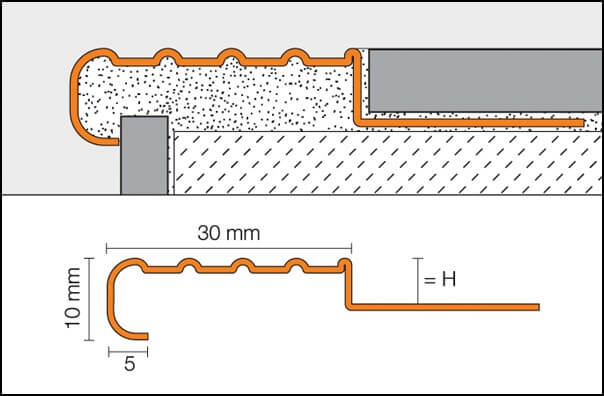

- Schlüter TREP-E must be chosen depending on the thickness of the tiles.

- The covering material should be placed on the step at the appropriate height.

- Adhesive should be applied in the area of the edge of the step.

- The hollow area below the profile must be filled with a suitable adhesive. Note regarding points 3 and 4: if a thick-layer adhesive is applied to the rungs of the steps, the hydraulic setting adhesive should be mixed with sand according to the manufacturer's instructions or medium-layer mortars should be used.

- Position Schlüter TREP-E by pressing and aligning the profile, so that the front of the profile extends beyond the tile of the riser, or alternatively place the flush profile with the riser.

- The trapezoidal perforated attachment wing should be completely covered with adhesive.

- Arrange the tiles so that they are flush with the top of the profile. In the delivery area with the profile there can be no gaps on the back of the tiles.

- A joint of approx. 2 mm between the tile and the profile.

- This joint must be completely filled with grouting material.

- In the case of placing Schlüter TREP-E in mortar screeds, the profile must be completely inserted into the mortar. The perforated side of the profile must be covered with mortar of at least 15 mm.

- In the case of using thin coverings, Schlüter TREP-E must be placed on the step so that the front of the profile is at the same height as the riser. The perforated side of the profile must be completely covered with the covering material, so that it is at the same level as the profile. The profiles should be cleaned or degreased beforehand. As an alternative, the profile can also be flush with the riser. See drawing "Example of Schlüter TREP-E installation".

Directions for use of Schlüter TREP-EK / -EFK

- The edges of the steps should be cleaned and repaired if necessary.

- The back of the Schlüter TREP-EK / -EFK must also be cleaned and degreased if necessary.

- The profile is placed with a suitable adhesive depending on the support, eg. ex. with epoxy resin or with Schlüter KERDI-FIX (see product data sheet 8.3). The adhesive must be applied over the entire surface.

Note: the installed profile will protrude approx. 2.5 mm (2 mm when using Schlüter TREP-EFK) above the coating.

Maintenance

The Schlüter TREP-E and TREP-EK rung profiles do not require any special maintenance. Stainless steel surfaces exposed to the weather or aggressive substances should be cleaned regularly with non-aggressive cleaning products. Regular cleaning not only keeps stainless steel clean, but also reduces the risk of corrosion. In no case can cleaning products contain hydrochloric acid or hydrofluoric acid.

Contact with other metals, such as normal steel, should be avoided as it may cause rust to appear. The use of tools to remove mortar remains, such as spatulas and steel wool, should also be avoided. If necessary, Schlüter CLEAN-CP cleaning polish is available.