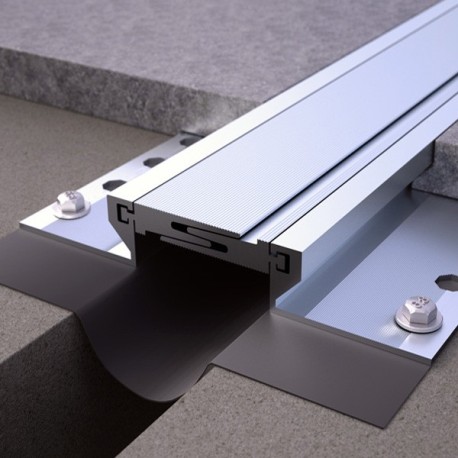

Expansion joint made entirely of aluminum, intended for placement in structural joints. Due to its design, it admits dimensional movements avoiding cracks as a consequence of the expansion and contraction of the construction elements.

This profile is ideal for applications with light and heavy traffic thanks to its outstanding load capacity. It can be installed with pavements of different thicknesses using the different combinable pieces available and its grooved face gives it anti-slip properties.

The profile is presented covered with protective film and with separators to support the installation. Available in matt or natural silver.

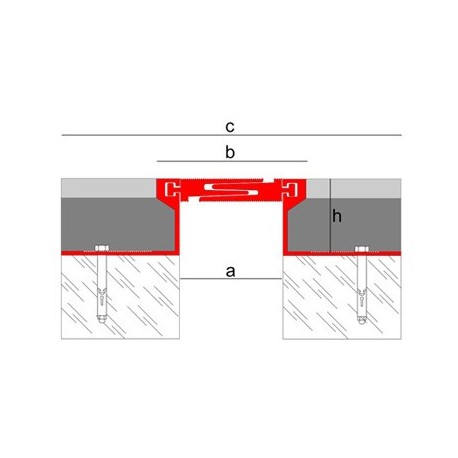

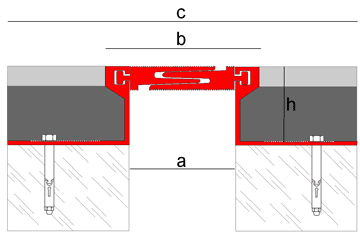

Dimensions

- a: 50 mm

- b: 71 mm

- c: 154 mm

- h: 20, 35, 50, 70 mm

- Length: 2,50 ml

Applications

Buildings and construction elements are subject to deformations and geometric variations. The arrangement of expansion joints contributes to reducing the effects that these variations have on the building as a whole, preventing the appearance of pathologies.

The CTE (Technical Building Code) in its DB-SAE (Building Actions), establishes that in concrete or steel buildings, expansion joints will be arranged so that there are no continuous elements of more than 40 m. of length.

Novojunta Pro Móvil is a solution for structural joints formed by a structure made up of several pieces of aluminum. This profile absorbs the stresses and deformations produced in the construction elements, preventing the appearance of cracks or other pathologies. It can be placed vertically and horizontally on both floor and wall tiles. The anodized finish is certified by Qualanod, which guarantees high resistance and durability both outdoors and indoors. This profile can be installed between floors of different thicknesses thanks to the possible combinations between pieces.

Novojunta Pro Móvil has a grooved face that gives it anti-slip properties, ideal for installation on pavements. Its excellent load capacity makes it suitable for light or heavy traffic, meeting the most demanding requirements.

Technical Characteristics and Tests

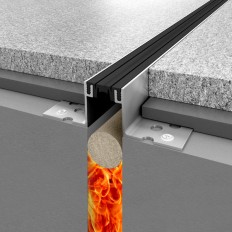

- Alloy: 6063 (L-3441 / 38-337)

- Fire resistance: M0 (UNE 23-727-90)

- Abrasion resistance: Very good *

- Light fastness: Excellent *

- Appearance and color: EN 12373-1 *

- Centered linear load (rigid wheel footprint): 7263N / AIMME

- Surface load 200x200 (footprint pneumatic wheel): 45102N / Adaptation of section 13.6.1 (Resistance to static load) of the UNE EN 60598-2-13: 2007 standard)

* Anodized aluminum

Materials

Novojunta Pro Móvil is a profile made using aluminum extrusion. The matte silver finish has been anodized, mainly improving through this process its resistance to corrosion, mechanical resistance and appearance. The anodizing carried out has the Qualanod quality seal, which guarantees the quality of the process and the resulting profiles. This seal regulates appearance and color tests, thickness measurements, sealing and impregnation control, resistance to abrasion, light fastness, acetic salt chamber and nitric acid immersion.

Aluminum is a material with excellent chemical and physical-mechanical properties. It is light, tough, ductile, malleable and highly durable. Its resistance to corrosion and fire is very good.

Aluminum is a highly valued material and used in various sectors, especially in construction. Its transformation processes are multiple, so that very different geometries can be obtained with high performance. It is a recyclable material.

Supported traffic

Novojunta Pro Móvil is capable of supporting light heavy traffic.

It allows category G traffic according to ACI Standard, American Concrete Institute, ACI 302.1R-89 and ACI 360.1R-92, for medium vehicles of net weight> = at 30 kN and <= at 160 kN, spread over two axles.

Trucks with pneumatic or rigid wheels of classification FL1, 2, 3 and 4 with net weight of up to 60 kN and load of up to 40 kN, with a total axle load of 90 kN, according to standard ACI 302.1R-89 and ACI 360R- 92.

It allows static overload of less than 5 t / m2 and the passage of vehicles on pneumatic wheels of less than 2.5 t / axle, as classified as average loads on screeds according to NTE-RSC.

Transport vehicles of up to 38 kN per axle, in single axle models. It can reach 60 kN per axis in the face of slow traffic.

This classification has been obtained from Standards ACI 302.1R-89 (Guide for concrete floors and construction slabs - American Concrete Institute - in reference to the classification of the magnitude of the load it can bear) and ACI 360.1R -92 (Design of the grades of floors, which describes the six common types of flooring for construction and refers to the actions induced by trucks and transport vehicles) and the classification of trucks (based on net weight, dimensions and cargo it carries).

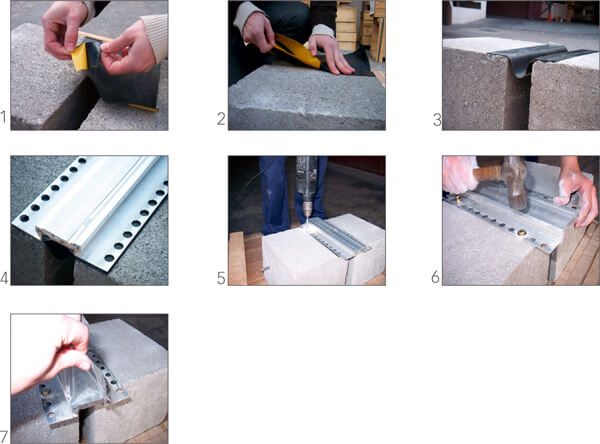

Installation

The Novojunta Pro Mobile model is supplied pre-assembled for easy installation. It incorporates plastic spacers on the exposed side to speed up the correct installation.

If you need to install a joint profile between floors of different thickness, you can do it by combining the different pieces available. Novojunta Pro Móvil combines features with versatility and can be installed in multiple situations.

Its installation can be with or without a sealing membrane, being an optional element although always recommended. The installation is the same, ignoring the steps regarding the placement of the membrane.

For installation with a sealing membrane:

- Thoroughly clean the surfaces where you are going to place the Novojunta Pro Móvil. Take the sealing membrane and remove the film that covers the area with adhesive.

- Place the sealing membrane on the sides of the joint, ensuring that proper adhesion occurs.

- Align the membrane correctly and leave a sufficient curve to allow its free movement.

- Place the profile on the already installed sealing membrane.

- Mechanize the holes for the fixing screws every 200 mm.

- Insert the fixing elements and anchor them following the manufacturer's recommendations. The use of Standard Fischer FSA 8/40 anchor or similar is recommended.

- Install the siding or pavement on both sides of the joint.

- Remove the protective film and plastic spacers from the surface of the Novojunta Pro Móvil.

The recommended anchors are dimensioned according to the stresses that the joint will have to support during its useful life. If you choose to use an alternative anchor, you should take it into consideration.

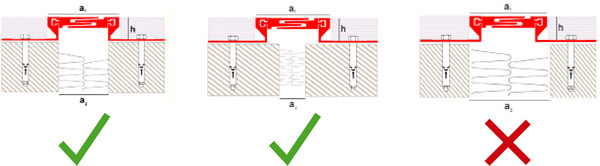

When choosing the required joint height, take into account the height that the anchors protrude above the fixing wing.

The width of Novojunta Pro Móvil is valid for joints of equal or less width. Never install this profile on a wider joint.

Cleaning and maintenance

Cleaning should be done periodically with a soft cloth. If you choose to use a neutral cleaning liquid, it should be rinsed with cold water and dried to remove excess moisture. Stubborn soiling can be removed with suitable mildly abrasive cleaning agents. If you apply a preservative, in addition to leaving a thin layer of water repellent, keep in mind that it should not be yellow, attract dust or dirt, or have iridescent effects.

The use of steel wool, abrasive or pickling products as well as strong acids (hydrochloric and perchloric), strong bases (caustic soda or ammonia) or carbonated solutions is not recommended. Citric acid should also not be used as it dissolves the protective oxide layer on the aluminum surface. Waxes, petroleum jelly, lanolin or the like are not suitable. Haloalkane solvents (hydrofluoroethers or chlorinated solvents) and setting accelerators containing chlorides should be avoided (use non-chloride accelerators).