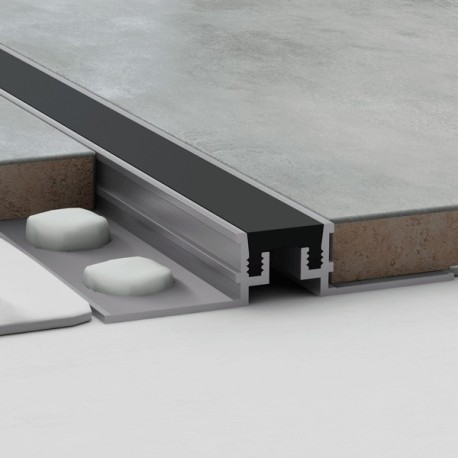

Expansion joint for flooring or cladding made of aluminum with a high-quality silicone rubber central body. Given the excellent properties of the material in which it is manufactured, the profile is ideal for absorbing the stresses and deformations of pavements and coatings, preventing the appearance of possible pathologies.

Available in black and gray colors with the possibility of custom colors on minimum order.

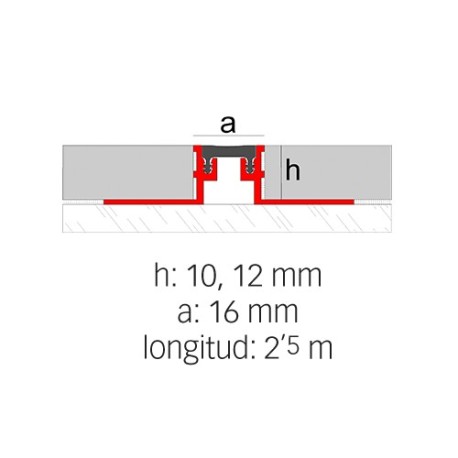

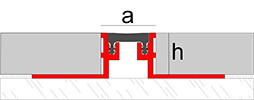

Dimensions

- a: 16 mm

- h: 10, 12, 15 mm

- Length: 2.50 ml

Applications

Solution for expansion joints in pavements and coatings, whose main function is to absorb the stresses and deformations caused by thermal variations to prevent the appearance of pathologies. It can be installed horizontally or vertically.

Technical characteristics

- Specific weight: 1.07 -2.05

- Hardness: 55-65 Shore A

- Surface: Non-porous. Non-stick.

- Working temperature: -55ºC / + 225ºC

- Weather and UV resistance: Excellent

- Ozone resistance: Excellent

- Electrical resistance: Excellent

- Water resistance: Water repellent

- Chemical resistance: Very good in general. Poor with hydrocarbons, acids, fats and solvents *

* This profile is not suitable for placement in environments where there may be the presence of oils, hydrocarbons, acids or solvents in any of its forms. For example, food industry related to oil refining, automotive workshops, etc.

Materials

The structure of this expansion joint is made by extrusion of aluminum. Aluminum is a material with excellent chemical and physical-mechanical properties. It is light, tough, ductile, malleable and highly durable. Its resistance to corrosion and fire is very good. Aluminum is a highly valued material and used in various sectors, especially in construction. Its transformation processes are multiple, so that very different geometries can be obtained with high performance. It is a recyclable material.

The elastic central body of the joint is made of high quality silicone rubber. Silicone is an elastomeric rubber with improved properties compared to other rubbers such as PVC or EPDM. Silicone rubber has mechanical properties similar to those of EPDM, it is functional at a working temperature of -55ºC to + 255ºC and is highly resistant to weather, UV rays and ozone. It is a non-porous, waterproof, non-stick, waterproof rubber with excellent behavior as an electrical insulator. By using additives it can be colored on demand (consult minimum quantity). Thanks to the properties of silicone, Novojunta Metallic Flex is indicated for any type of environment, especially outdoors due to its extreme durability. Placement in environments where there may be the presence of oils, hydrocarbons, acids or solvents in any of their forms. For example, food industry related to oil refining, automotive workshops, etc.

Installation

- - Spread abundant gripping material on the surface where you are going to install the flooring or covering.

- - Next, position the profile and press it so that the gripping material passes through the fixing wing dies.

- - Place a tile on the profile fixing wing and press for optimal contact with the bonding material.

- - Repeat the operation placing tiles on both sides of the profile until the installation is complete. Before setting occurs, gently tap with a rubber hammer to flush the profile with the pavement.

- - Finally clean the excess material, remove the protective film and allow to dry.

Cleaning and maintenance

Cleaning should be done periodically with a soft mop and a neutral cleaning liquid, rinsing well with cold water and drying well to remove excess moisture.

The use of steel wool, abrasive or stripping products, as well as most strong acids, strong bases (caustic soda or pure ammonia) or carbonated solutions is not recommended. The use of all types of solvents as well as setting accelerators containing chlorides (use non-chloride accelerators) should be avoided, as they could damage the exposed part of the aluminum.