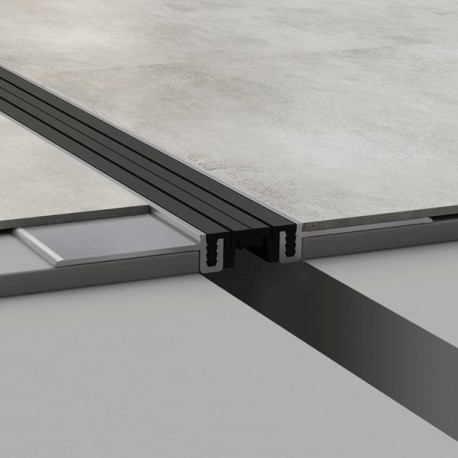

Structural expansion joints made up of 2 light aluminum profiles with a high-performance rubber insert with a large capacity for admitting multidirectional movements.

The rubbers, available in black or gray, ready or ribbed, are replaceable and are supplied in continuous rolls.

This expansion joint is served WITHOUT ASSEMBLING. It is made up of lightweight “L” aluminum profiles, with a high-performance rubber insert capable of admitting multidirectional movements, excellent mechanical properties, resistant to weathering and UV rays. This joint is 3 mm high, making it ideal for laying with low-thickness floors such as vinyl flooring or carpeting, among others. The complete kit includes all the fixings. The rubbers are replaceable and are supplied in continuous rolls.

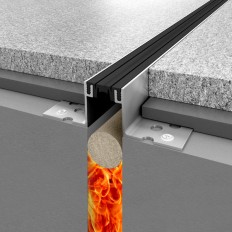

Fireproof cord available (Consult).

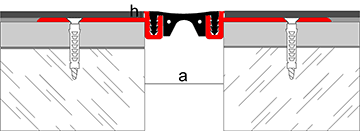

Dimensions

- a: 20, 30, 40 mm.

- h: 3 mm.

- Length: 2.50 ml

Movement admitted by the structural expansion joint

- Width 20: 8 mm. (+/- 4 mm) SMOOTH RUBBER // 10 mm (+ / 5 mm) RIBBED RUBBER

- Width 30: 10 mm. (+/- 5 mm) SMOOTH RUBBER // 12 mm (+ / 6 mm) RIBBED RUBBER

- Width 40: 12 mm. (+/- 6 mm) SMOOTH RUBBER // 14 mm (+ / 7 mm) RIBBED RUBBER

Technical characteristics

- Abrasion resistance: Excellent

- Weather resistance: Very good

- Elasticity: very good

- Working temperature: -50ºC / +80 ºC

Applications

Buildings and construction elements are subject to deformations and geometric variations. The arrangement of expansion joints contributes to reducing the effects that these variations have on the building as a whole, preventing the appearance of pathologies.

The CTE (Technical Building Code) in its DB-SAE (Building Actions), establishes that in concrete or steel buildings, expansion joints will be arranged so that there are no continuous elements of more than 40 m. of length.

Novojunta Pro Basic Slimm is a solution for structural joints made up of two overlapping pieces of aluminum joined by a synthetic rubber profile with movement capacity. This profile absorbs the stresses and deformations produced in the construction elements, preventing the appearance of cracks or other pathologies. Ideal for placement on floors, walls and ceilings.

Novojunta Pro Basic Slimm is a lightweight, easy-to-fit overlay profile suitable for light / medium load transit. It is indicated for placement on site in structural joints with micro-thickening pavements such as vinyl, carpets, etc.

Materials

Aluminum

The Novojunta Pro Basic Slimm side profiles are made of aluminum extrusion. Aluminum is a material with excellent chemical and physical-mechanical properties. It is light, tough, ductile, malleable and highly durable. Its resistance to corrosion and fire is very good.

Aluminum is a highly valued material and used in various sectors, especially in construction. Its transformation processes are multiple, so that very different geometries can be obtained with high performance. It is a recyclable material.

Synthetic rubber

The central body of Novojunta Pro Basic Slimm is made of high quality synthetic rubber. This rubber has the ability to absorb multidirectional movements and has excellent mechanical properties: great elasticity, moderate resistance to weathering, resistance to moisture and wear due to abrasion and thermal variations (-50ºC / + 80ºC).

Load support

This expansion joint supports light / medium loads, including pedestrian and vehicular traffic. It allows the passage of vehicles with pneumatic wheels (DIN 1072) up to 30 kN.

Installation

The Novojunta Pro Basic Slimm model is delivered disassembled for assembly on site. Each complete profile is 2.5 ml with the corresponding fixings.

- Clean the surfaces where you will install the gasket.

- Place the profiles aligned with the edge of the joint. -Make sure that the width is adequate to later accommodate the rubber.

- Machine the holes for the fixing hardware.

- Fix the gasket with the supplied fixings

- Place the flooring and top it with the aluminum profile.

- Finally, insert the rubber into the grooves of the aluminum profiles and align it with the surface. You can use a rubber hammer.

Cleaning and maintenance

Cleaning should be done periodically with a soft mop and a neutral cleaning liquid, rinsing well with cold water and drying well to remove excess moisture. Stubborn soiling can be removed with suitable mildly abrasive cleaning agents.

The use of steel wool, abrasive or pickling products as well as strong acids (hydrochloric and perchloric), strong bases (caustic soda or ammonia) or carbonated solutions is not recommended. Citric acid should also not be used as it dissolves the protective oxide layer on the aluminum surface. Waxes, petroleum jelly, lanolin or the like are not suitable. Haloalkane solvents (hydrofluoroethers or chlorinated solvents) and setting accelerators containing chlorides should be avoided (use non-chloride accelerators).