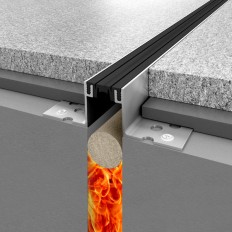

Structural joints profile, consisting on two profiles made of aluminium and a central body made of high quality EPDM which maintains the joint hidden in a clean and aesthetic way.

It absorbs deformations and geometric variations in 3 axis. This profile has the more suitable technical features such as: resistance to light and medium traffic, dimensional movements to protect structural elements, tightness, abrassion resistance, fire resistance, durability or non-slip properties.

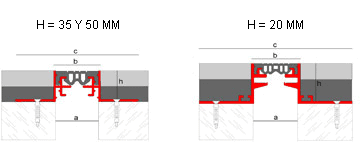

It can be installed between two tiles with different thickness, thanks to the lateral pieces combinable available in different heights. It is delivered pre-ensambled, for an easy installation and with protective film on its surface. To find out more, check the Technical File.

Available in matt silver aluminium and black rubber.

Joints up to 30 mm wide

| Material | Joint width (a) | Visible width (b) | Total width (c) | Height (h) | Packaging |

| Aluminum + Rubber EPDM | 30 mm. | 34 mm. | 87 mm. | 20 mm. | 6 ud. |

| 130 mm. | 35 mm. | 2 ud. | |||

| 130 mm. | 50 mm. |

Joints up to 40 mm wide

| Material | Joint width (a) | Visible width (b) | Total width (c) | Height (h) | Packaging |

| Aluminum + Rubber EPDM | 40 mm. | 44 mm. | 97 mm. | 20 mm. | 6 ud. |

| 140 mm. | 35 mm. | 2 ud. | |||

| 140 mm. | 50 mm. |

Joints up to 55 mm wide

| Material | Joint width (a) | Visible width (b) | Total width (c) | Height (h) | Packaging |

| Aluminum + Rubber EPDM | 55 mm. | 59 mm. | 155 mm. | 35 mm. | 2 ud. |

| 155 mm. | 50 mm. | 1 ud. |

Materials

Novojunta Pro Aluminum is a profile made by extrusion of aluminum. Aluminum is a material with excellent chemical, physical and mechanical properties. It is lightweight, tough, ductile, malleable and highly durable.

Aluminum is a high valued raw material and it is widely used in several sectors, specially for construction. Its transformation processes are multiple, so it can get very different geometries with high performance. This is a recyclable material.

The central body of Novojunta Pro Aluminium is made of high quality EPDM rubber. EPDM is an elastomeric polymer with excellent mechanical properties. It has good resistance to abrasion, wear and impact, is well insulated, is weather resistant to most common chemicals and it has a wide working temperature.

His excellent recovery after compression is the key to absorb deformations and geometric variations of the construction elements.

Traffic loads supported

Novojunta Pro Aluminum (h 3/4”) is able to support light loads.

It allows traffic category F, according to ACI (American Concrete Institute) Standards 302.1R-89 and 360.1R-92, for light vehicles with load <= 30 kN and <= 8 seats excluding the driver.

Trucks classification FL1 according to ACI (American Concrete Institute) Standards 302.1R-92 and 360.1R-92, with pneumatic or rigid wheels with net weight 21 kN and load up to 10 kN. It allows static load lower than 1t/m2 and the pass of vehicles with pneumatic wheels minor than 1t/axis, according to the classification of light loads over floors (NTE-RSC).

Focused linear load 0,5 kN.

Novojunta Pro Aluminum (h1-3/8” and 2”) is able to support traffic of medium loads.It allows traffic category G according to ACI (American Concrete Institute) Standards ACI 302.1R-89 and 360.1R-92, for medium vehicles with load >30kN and >160 kN spreaded on two axis.Trucks with rigid or pneumatic wheels, classified as FL1,2 and 3 according to ACI Standard, American Concrete Institute ACI 302.1R-89 and 360.1R-92, with net weight of 44 KN and load up to 25 kN, with a total load per axes of 63 kN. Allows static overload under 5t/m2 and the passage of vehicles with pneumatic tires of less than 2.5 t / axle, as classified as medium loads on trays as NTE-RSC.

Focused linear load 0,8 kN.

This classification has been obtained from Standards ACI 302.1R-89 (Guide for concrete floors and construction slabs, referring to the magnitude of the load they can support) and ACI 360.1R-92 (De-sign of the different degrees of floors, which describe the six common types of floors for construction referred to the actions induced by trucks and transport vehicles) and the classification of trucks (de-pending on the net weight, dimensions and load which transport).

Installation

Novojunta Pro Aluminio it is delivered ensambled and it is easy to install.

Its installation can be with or without sealant membrane. This is an optional element but always recom-mendable. The sealant membrane avoids the loss of hermeticity in joints and corners and achieves a perfect sealing.

Installation with sealant membrane:

- - Clean the surfaces where the Novojunta Pro Aluminum will be installed. Take the sealant membrane and remove the film which covers the area with adhesive.

- - Place the sealant membrane on the sides of the joint and ensure it gets a perfect adhesion.

- - Align correctly the sealant membrane and keep a curve shape enough to allow its free movement.

- - Place the profile over the sealant membrane previously installed.

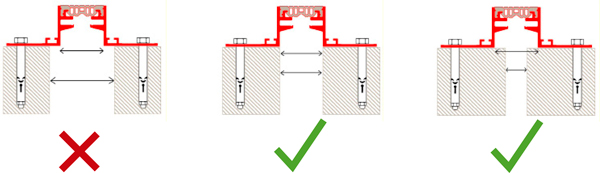

- - Mechanize the holes for the anchoring fasteners every 400 mm. (Novojunta Pro Aluminium h:20 mm.) or every 500 mm. (Novojunta Pro Aluminium h:35,50 mm.)

- - Insert the fasteners and fix it following the recommendations of the manufacturer. It is recommended to use Fischer SX 6x30 o similar (Novojunta h3/4”) or metallic screw Standard Fischer FSA 8/40 (Novojunta h1-3/8” and 2”.)

- - Install the tiles in the flooring or the wall both sides of the joint.

- - Remove the protective film.

The width of Novojunta Pro Aluminum, is valid for joints whose width is equal or smaller. Do never install this profile in a joint with higher width than the profile.

Cleaning and maintenance

The cleaning must be done periodically with a soft cloth or mop. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry to remove excess moisture. If dirtiness persists, clean the profile with a solution with clean water and detergent or neutral soap 5%, brushing with a cloth that has no particles that could scracht the finish.

Steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is neither recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).