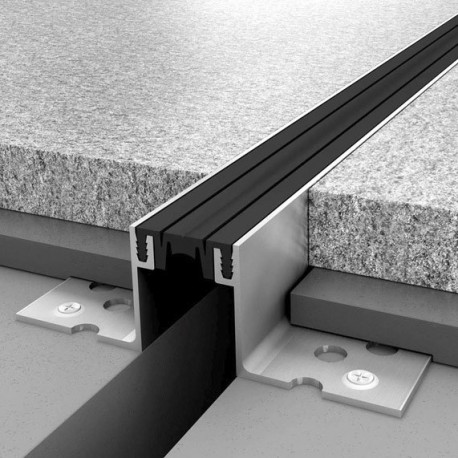

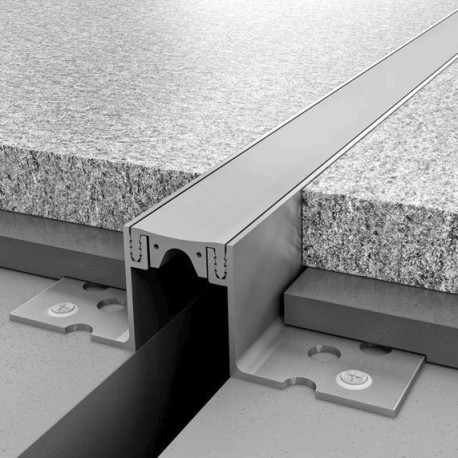

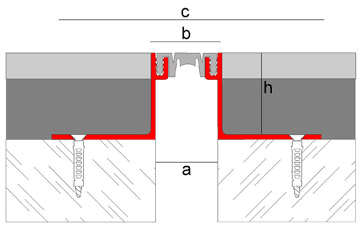

System of profiles intended to be installed in expansion joints up to 45 mm width. It consists of two aluminum profiles holed on the base for the fixing screws with a synthetic rubber insert that absorbs multidirectional movements.

This range is highly functional since both aluminum and rubber profiles can be combined. So if we have a expansion joint between two slabs of different height, we can purchase different pieces according to our needs The synthetic rubber resists weathering, thermal changes, wear and moisture.

The flat finishes are the most appropriate choice for places with high hygienic requirements like hospitals.

Available in black or grey colour, with flat or striated finish.

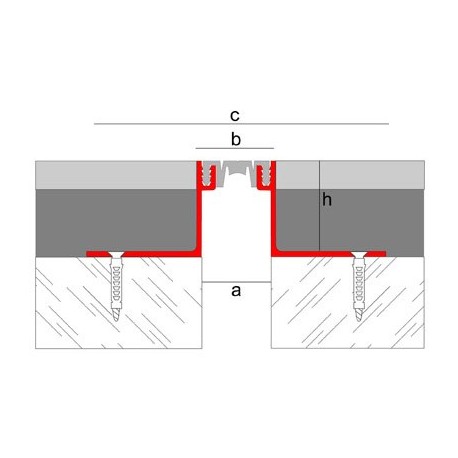

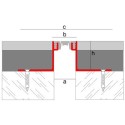

Dimensions

| Profile height (h) | Joint width (a) | Visible width (b) | Overall width (c) | Rubber type | Flat rubber movement | Striated rubber movement |

| 12,50 mm | 20 mm | 24 mm | 104 mm | Flat/striated | 8 mm (+/-4) | 10 mm (+/-5) |

| 22 mm | 20 mm | 24 mm | 104 mm | Flat/striated | 8 mm (+/-4) | 10 mm (+/-5) |

| 40 mm | 20 mm | 24 mm | 120 mm | Flat/striated | 8 mm (+/-4) | 10 mm (+/-5) |

| 50 mm | 20 mm | 24 mm | 160 mm | Flat/striated | 8 mm (+/-4) | 10 mm (+/-5) |

| 80 mm | 20 mm | 24 mm | 130 mm | Flat/striated | 8 mm (+/-4) | 10 mm (+/-5) |

| 12,50 mm | 30 mm | 34 mm | 114 mm | Flat/striated | 10 mm (+/-5) | 12 mm (+/-6) |

| 22 mm | 30 mm | 34 mm | 114 mm | Flat/striated | 10 mm (+/-5) | 12 mm (+/-6) |

| 40 mm | 30 mm | 34 mm | 130 mm | Flat/striated | 10 mm (+/-5) | 12 mm (+/-6) |

| 50 mm | 30 mm | 34 mm | 170 mm | Flat/striated | 10 mm (+/-5) | 12 mm (+/-6) |

| 80 mm | 30 mm | 34 mm | 140 mm | Flat/striated | 10 mm (+/-5) | 12 mm (+/-6) |

| 12,50 mm | 40 mm | 44 mm | 124 mm | Flat/striated | 12 mm (+/-6) | 14 mm (+/-7) |

| 22 mm | 40 mm | 44 mm | 124 mm | Flat/striated | 12 mm (+/-6) | 14 mm (+/-7) |

| 40 mm | 40 mm | 44 mm | 140 mm | Flat/striated | 12 mm (+/-6) | 14 mm (+/-7) |

| 50 mm | 40 mm | 44 mm | 180 mm | Flat/striated | 12 mm (+/-6) | 14 mm (+/-7) |

| 80 mm | 40 mm | 44 mm | 150 mm | Flat/striated | 12 mm (+/-6) | 14 mm (+/-7) |

Applications

The buildings and constructive elements are under strains caused by thermal variations. The installa-tion of expansion joints helps to minimize the effects that these variations cause in the whole building, preventing a possible structural damage.

The CTE (Spanish Technical Code of Building), in the DB-SAE (Document about actions in building), states that in steel or concrete buildings is necessary not to let continuous elements longer than forty meters without installing expansion joints.

Novojunta Pro Basic is a solution for expansion joints consisting of two aluminum profiles holed on their base to receive the screws, together by a rubber with the ability to move. This profile absor-bs expansions and contractions caused by constructive elements, preventing the cracking and other pathologies. Suitable to be installed in floors, walls and ceilings.

Novojunta Pro Basic is a system for expansion joints, easy to install and suitable for traffic of light/medium loads. To be installed during the work. Flush with the flooring.

Technical Features

- Abrasion resistance: Excellent

- Weatherability: Very good

- Elasticity: Very good

- Working temperature: -50ºC / +80 ºC

Materials

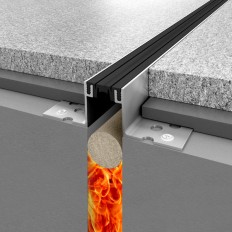

Aluminium

The side profiles of Novojunta Pro Basic are manufactured by aluminum extrusion. The aluminum is a raw material with excellent chemical and physicomechanical properties. It is light, tough, ductile, malleable and highly durable. It has a great resistance to fire and corrosion

Aluminum is a high valued raw material and it is widely used in several sectors, specially construction. Its transformation processes are multiple, so it can get very different geometries with high performan-ce. This is a recyclable material.

Synthetic rubber

The rubber of Novojunta Pro Basic is made of high quality rubber. This rubber can absorb multidi-rectional movements and has excellent mechanical properties: great elasticity, moderate weatherabili-ty, moisture and abrasion resistance and is also resistant to thermal variations (-50ºC/+80ºC).

Load support

Novojunta Pro Basic can support light and medium loads, which means that allows pedestrian and vehicular traffic. Allows the traffic of vehicles with pneumatic wheels (DIN 1072) up to 35 kN and the ocasional traffic of heavy loads with pneumatic wheel.

Installation

Novojunta Pro Basic is delivered unmounted. This allows multiple combinations with the profiles and the different rubbers, that can adapt to the customer requirements.

- Clean the surfaces to install the profile.

- Place both profiles aligned to the borders of the expansion joint. Be sure the width is the suitable to install the rubber.

- Make the holes for the fixing screws.

- Fix the expansion joint with the screws supplied.

- Continue with the flooring until it is finished6. Finally, insert the rubber into the grooves of the aluminum profiles and align all with the surface. You can use a rubber hammer.

Cleaning and maintenance

The cleaning must be done periodically with a soft cloth. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry to remove excess moisture. If dirtiness persists, clean the profile with a solution with clean water and detergent or neutral soap 5%, brushing with a cloth with no particles that could scratch the finish. Outdoors, rainfall will clean the profile.

Steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is neither recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).