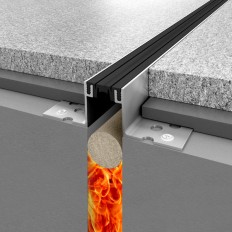

Maintenance free movement profile to bridge structural joints within tile and natural stone coverings. Schlüter DILEX-KSBT assists in reducing the transmission of impact sound.

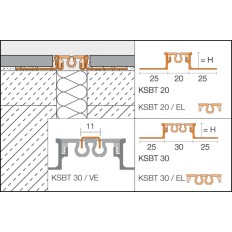

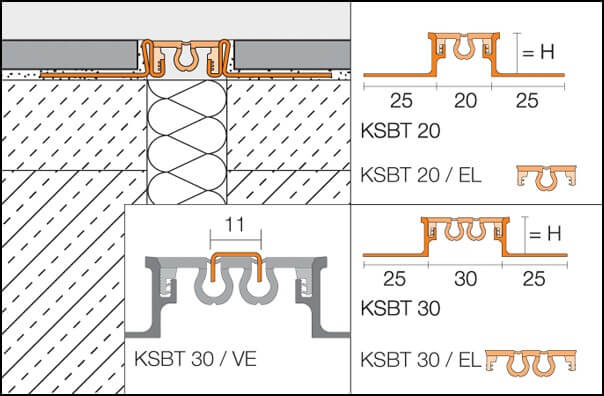

If the closed movement zone is unable to absorb movements, the joint spacer can be cut open. In this manner, the 20 mm wide insert can absorb movements of ± 5 mm and the 30 mm wide insert, movements of ± 10 mm.

The profile can be used in floor areas as well as wall areas, for a continuous, uniform appearance. It is particularly suited for use in walls and ceilings made from gypsum board panels; it can also be integrated directly into the plaster or mortar screed.

The trapezoid perforated anchoring legs, made of stainless steel or aluminium, are connected by a 20 mm or 30 mm wide, soft movement zone made of thermoplastic rubber.

The rubber insert can be replaced in case of damage.

The anchoring metal legs effectively protect the adjoining edges of the floor covering. The broad movement zone limits the load bearing capacity of the profile when subjected to high point loads or when heavy weights are placed directly on the soft zone. A reinforcement cover strip is available for the 30 mm wide profile and additional measures can be adopted for the 20 mm wide profile, please contact us for advice.

Material

E = Stainless steel

V2A, material no. 1.4301 = AISI 304

V4A material no. 1.4404 = AISI 316L

A = Aluminium

The movement zone consists of soft thermoplastic rubber with grip bars made of a rigid material.

Material properties and areas of application

The suitability of a proposed type of profile must be verified based on the anticipated chemical, mechanical, and/or other stresses.

Schlüter DILEX-EKSBT with stainless steel support profiles made of material no. 1.4301 (V2A) or 1.4404 (V4A) are especially suitable for applications that require, in addition to high mechanical durability, resistance to chemical stresses from sources such as acidic or alkaline media or cleaning agents. The use of V4A is recommended if consistent exposure is expected, for example in the case of swimming pools (fresh water). Stainless steel is not resistant to all chemical stresses, and may be affected by hydrochloric and hydrofluoric acid or certain chlorine and brine concentrations. Special anticipated stresses should therefore be verified in advance. Depending on the anticipated chemical stresses, customers can choose between the alloy materials 1.4301 or 1.4404.

Schlüter DILEX-AKSBT, with aluminium anchoring legs, must be tested to verify its suitability if chemical stresses are anticipated. Cementitious materials, in conjunction with moisture, become alkaline. Since aluminium is sensitive to alkaline substances, exposure to the alkali (depending on the concentration and duration of exposure) may result in corrosion (aluminium hydroxide formation). For this reason, remove mortar or grouting material immediately from all visible areas and do not cover freshly installed coverings with foil. The profile must be solidly bedded in the setting material.

Schlüter DILEX-KSBT 30 / VE is a Ushaped profile insert of brushed stainless steel. It is used to enhance optical appeal and reinforces the soft core of the profiles DILEX-KSBT 30. The movement zone of all Schlüter DILEX-KSBT profile types consists of highly flexible thermoplastic rubber. This material is highly resistant to chemicals and the chemical stresses typically associated with tile coverings and has been specially treated to resist fungi and bacteria. The insert is resistant to temperatures ranging from -60 °C to +100 °C. Thermoplastic elastomers can be connected by welding if profiles are joined to produce longer lengths.

Installation

- Select Schlüter DILEX-KSBT in accordance with tile thickness.

- Using a notched trowel, apply tile adhesive to the area where the profile will be placed.

- Press the trapezoid-perforated anchoring leg of Schlüter DILEX-KSBT firmly into the adhesive and align it. The profile must align directly with expansion and movement joints in the substrate below.

- Trowel tile adhesive over the trapezoid perforated anchoring leg to ensure full coverage. Trowel tile adhesive against the vertical anchoring legs at an angle.

- Firmly press the adjoining tiles into place and align them in such a way that the upper profile edge is flush with the tile (profile should not protrude over the surface of the covering; preferably, it should be approx. 1 mm below the top level of the covering). The tiles must be fully embedded in the area of the profile. Always adjoin the uncut tile edge to the profile.

- Leave a 2-mm joint to the profile, and completely fill the joint between the profile and the tile with mortar.

- For installation of the profile insert Schlüter DILEX-KSBT 30 / VE into the profile Schlüter DILEX-KSBT 30, cut the grooves of the soft zone with a utility knife. Apply the installation adhesive Schlüter®KERDI-FIX to the back of the profile insert and press it into the groove.

- For cross joints, trim the profiles in such a way that the trapezoid perforated anchoring legs don’t overlap during installation.

Maintenance

Schlüter DILEX-KSBT is treated to resist fungi and bacteria, and requires no special maintenance or care. The synthetic rubber movement zone is replaceable.

Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner.

Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid. Avoid contact with other metals such as steel, since this can cause extraneous rust.

This also includes tools such as trowels or steel wool, i.e. tools used to remove mortar residue.