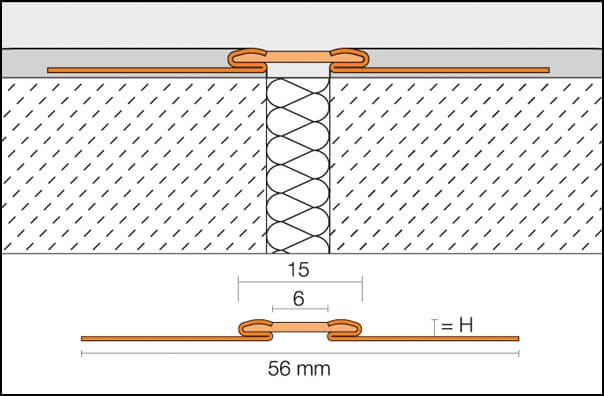

Movement profile with edge protection for floor coatings and other thin floor coverings. It consists of lateral stainless steel anchoring legs that are connected to a fixed elastic insert of soft synthetic material.

Material

E = Stainless steel

- V2A, material no. 1.4301 = AISI 304

- V4A, material no. 1.4404 = AISI 316L

A = Aluminium

- The movement zone consists of highly flexible thermoplastic rubber with inserts made of a harder material.

Material properties and areas of application

The suitability of a proposed type of profile must be verified based on the anticipated chemical, mechanical and/or other stresses. Schlüter DILEX-EKSN/-EKSB/-EKSA with stainless steel support profiles made of material no. 1.4301 (V2A) or 1.4404 (V4A) are especially suitable for applications which, in addition to high mechanical durability, require resistance to chemical stresses from sources such as acidic or alkaline media, cleaning detergents, or de-icing salt. The use of V4A is recommended if consistent exposure is expected, for example in the case of swimming pools (fresh water). Even stainless steel is not resistant to all chemical stresses, and may be affected by hydrochloric and hydrofluoric acid or certain chloride and brine concentrations. Special anticipated stresses should therefore be verified in advance. Depending on the anticipated chemical stresses, customers can choose between the alloy materials 1.4301 V2A or 1.4404 V4A.

Schlüter DILEX-AKSN/-AKSA with lateral anchoring leg profiles of aluminium are sensitive to alkaline media. Cementitious materials, in conjunction with moisture become alkaline. Since aluminium is sensitive to alkaline substances exposure to the alkali (depending on the concentration and duration of exposure) may result in corrosion (aluminium hydroxide formation). For this reason, remove mortar or grouting material immediately from all visible areas and do not cover freshly installed coverings with foil. It must be ensured that the profile is solidly embedded in the setting material to prevent alkaline water from accumulating in small cavities. The movement zones of all Schlüter DILEX-KS and -KSA profile types consist of highly flexible thermoplastic rubber. This material is UV-resistant, suitable for outdoor use, and resistant to the chemical stresses typically associated with tile coverings and has been specially treated to resist fungi and bacteria.

The insert is resistant to temperatures ranging from -60 °C to +100 °C. The thermoplastic elastomer can be heat bonded to extend the profile length.

The tile inserts Schlüter DILEX-KS/K are available in all colours for cross joints created with the movement profiles Schlüter DILEX-KS.

Installation Schlüter DILEX-KS

Installation for tile and natural stone surfaces:

- Select Schlüter DILEX-KS according to the tile thickness.

- Apply tile adhesive to the area where profile is to be installed, using a notched trowel.

- Press the trapezoid perforated anchoring leg of Schlüter DILEX-KS firmly into the adhesive and align it. The profile must align directly with expansion and movement joints in the substrate below.

- Trowel tile adhesive over the trapezoid perforated anchoring leg to ensure full coverage. Trowel tile adhesive against the vertical anchoring legs at an angle.

- Firmly press the adjoining tiles into place and align them in such a way that the upper profile edge is flush with the tile (profile should not protrude over the surface of the covering; preferably, it should be approx. 1 mm below the top level of the covering). The tiles must be fully embedded in the area of the profile. Always adjoin the uncut tile edge to the profile.

- Leave a 2-mm joint to the profile, and completely fill the joint between the profile and the tile with mortar.

- When creating cross joints, trim the profiles to ensure that the trapezoidperforated anchoring legs do not overlap in installation. The tile inserts Schlüter DILEX-KS/-K are available in all colours for neat joint appearance.

Installation for coatings:

- Select Schlüter DILEX-KS according to the thickness of the covering.

- Apply a contact layer in the area where profile is to be installed.

- Press the trapezoid perforated anchoring leg of Schlüter DILEX-KS firmly into the adhesive and align it. The profiles may need to be cleaned and degreased prior to installation. The profile must align directly with expansion and movement joints in the substrate below.

- Trowel coating material over the trapezoid perforated anchoring leg. The finished surface coating should be flush with the upper edge of the profile.

Note:

The profile should not be higher than the coating surface but flush or up to approx. 1 mm lower.

Installation Schlüter DILEX-KSA

- Select Schlüter DILEX-KSA according to the tile thickness.

- Apply tile adhesive to the area where the profile is to be installed, using a notched trowel.

- Peel off the silicone paper of the selfadhesive strip at the profile. Attach the profile to the cleaned structural element with the self-adhesive strip in such a way that the trapezoid perforated anchoring leg can be pressed into the fresh tile adhesive.

- Trowel tile adhesive over the trapezoid perforated anchoring leg to ensure full coverage. Trowel tile adhesive against the vertical anchoring legs at an angle.

- Firmly press the adjoining tiles into place and align them in such a way that the upper profile edge is flush with the tile (profile should not protrude over the surface of the covering; preferably, it should be approx. 1 mm below the top level of the covering). The tiles must be fully embedded in the area of the profile. Always adjoin the uncut tile edge to the profile.

- Leave a 2-mm joint to the profile, and completely fill the joint between the profile and the tile with mortar.

Maintenance

Schlüter DILEX-KS and Schlüter DILEX-KSA are specially treated to resist the growth of fungi and bacteria and require no special maintenance or care.

The movement zone of thermoplastic rubber can be subsequently replaced (except for sizes 2.5, 4.5 and 6 mm).

Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner. Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion.

All cleaning agents must be free of hydrochloric and hydrofluoric acid. Avoid contact with other metals, such as regular steel, to prevent corrosion. This also includes installation tools such as trowels or steel wool, e.g., for the removal of mortar residue.

We recommend the use of the stainless steel cleaning polish Schlüter CLEAN-CP.