Maintenance-free, stainless steel movement profile for absorbing horizontal movement. The profile is particularly suited for tile and natural stone surfaces subject to heavy use.

Schlüter DILEX-EDP offers secure edge protection for surfaces exposed to continuous vehicle traffic and is, therefore, suited for use in warehouses, shopping centres, underground car parks or for floor surfaces maintained with cleaning machines.

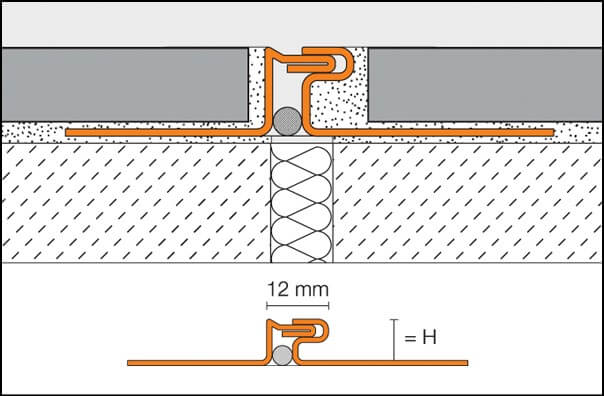

Movements within the floor covering are absorbed by the tongue-and-groove connection. The visible width of the Schlüter DILEXEDP profile in its base position is 12 mm.

Due to the tongue-and-groove mechanism, the profile cannot absorb vertical movement. Therefore, appropriate measures must be taken to prevent vertical movement of the screed.

The side sections of the profile are specially designed to protect the edge areas of the surface covering.

Material

Schlüter DILEX-EDP is available in the following material:

E = stainless steel V2A, material no. 1.4301 = AISI 304

Material properties and areas of application

Schlüter DILEX-EDP is made of stainless steel material no. 1.4301, which is roll-formed from strip metal and features trapezoid perforations in the area of the anchoring legs. The profile is highly durable and especially suited for application areas that must be resistant to chemicals and acids, such as the food industry, breweries, dairies, industrial kitchens, and hospitals as well as residential spaces.

Even stainless steel is not resistant to all chemical stresses, and may be affected, e.g., by hydrochloric and hydrofluoric acid or certain chloride and brine concentrations. In certain cases, this also applies to seawater pools. Special anticipated stresses should therefore be verified in advance.

Installation

- Select Schlüter DILEX-EDP according to tile thickness.

- Using a notched trowel, apply tile adhesive to the area where the profile will be placed.

- Press the perforated anchoring legs of Schlüter DILEX-EDP into the adhesive bed and align. The profile must align directly with expansion and movement joints in the substrate below.

- Completely cover the perforated anchoring legs with tile adhesive. Apply tile adhesive to the vertical profile section at an angle.

- Firmly press the adjoining tiles into place and adjust them in such a way that the upper lip of the profile is flush with the tile (Note: The profile should not be higher than the tile, but rather flush or up to approx. 1 mm lower). All tiles in the profile area must be solidly bedded. Always lay the uncut section of a tile against the profile.

- Leave a joint of approx. 2 mm between the tile and the profile; fill the joint completely with grout.

Maintenance

Schlüter DILEX-EDP requires no special maintenance or care. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner.

Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid.

Avoid contact with other metals such as steel, since this can cause extraneous rust. This also includes tools such as trowels or steel wool, i.e., tools used to remove mortar residue.