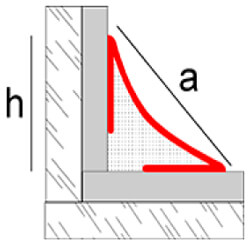

Profile with smoothed curve and reduced face side, made of Aluminum. The perfect technology applied on its surface protects against microorganisms and bacterias. Designed for its placement in joints wall-floor, floor-floor to make the cleaning and maintenance of corners easier. Its placement without work makes it perfect for rehabilitation or reform. It is ideal for public installations or homes. Available in white and matt silver finish.

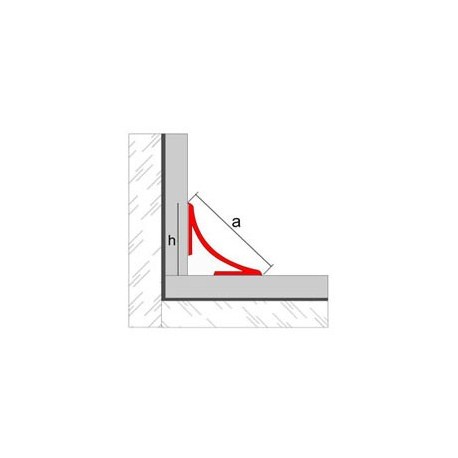

Dimensions

- h: 27 mm

- a: 38 mm

- Long: 2,50 ml

Applications

Scope of Novoescocia 4 Aluminum:

- Corners between walls and kitchen countertops.

- Perimeters in shower trays or bathtubes.

- Encounters: wall-floor, wall-wall or wall-ceiling botn horizontally and vertically.

It is an ideal product for bathrooms, kitchens, medical consultations, restaurants... It has a versatile design which is appropriate for homes, offices, public buildings or installations with high requirements of hygiene and cleaning such as garbage rooms, cold storages, communities, etc.

Novoescocia 4 aluminum helps to fulfill with the DB-HS document of the CTE (Spanish Technical Building Code), improving the value of cleaning and desinfection of the pavements where is installed.

Materials:

Novoescocia 4 aluminum is a profile made by extrusion of aluminum. Matt silver finish has been anodized, improving through this process their corrosion resistance, mechanical resistance and appearance. It has the quality seal Qualanod, which guarantees the quality of the process and the resulting profiles. This seal regulates several tests: appearance and color, thickness measurements, sealing and impregnation control, abrasion resistance, lightfastness, acetic saline chamber and nitric acid immersion.

On the other hand, lacquered finish obtains a high quality and homogeneus surface. The lacquering has the quality seal Qualicoat, which guarantees the quality of the process and the final products.

Aluminum has excellent chemical, physical and mechanical properties. It is lightweight, tough, ductile, malleable and highly durable.

The complementary pieces of Novoescocia 4 aluminum are made of Zamak. The zamak is a non ferrous alloy of zinc with aluminium, magnesium and copper (UNE EN 1774). It is tough, has high hardness, high mechanical strength and excellent plastic deformability.

Technical features and Tests

- Alloy: 6063 (L-3441/38-337)

- Fire resistance: M0 (UNE 23-727-90)

- Abrasion resistance*: Very good

- Lightfastness*: Excellent

- Appearance and color*: EN 12373-1

*Anodized aluminum

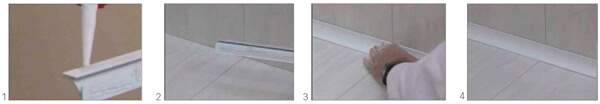

Installation

Please, clean the surface destinated to the installation of Novoescocia 4 aluminum:

- Cover generously the back face of Novoescocia 4 aluminum with an adhesive silicone type “MS Sealing/Express Adhesive” from Fischer or similar.

- Fill also the posterior cavity with the same adhesive to ensure a perfect sealing and good grip.

- Place the Novoescocia 4 aluminum on the corner and press firmly ensuring a good contact between both surfaces

- Finally clean the remaining material and let dry.

* In humid environments or in direct touch with water, it is recommended to seal the joints between Novoescocias with silicones.

Cleaning and maintenance

The cleaning must be done periodically with a soft cloth. If you use a neutral liquid cleaner, you must rinse the profile with cold water and dry to remove excess moisture. If dirtiness persists, clean the profile with a solution with clean water and detergent or neutral soap 5%, brushing with a cloth that has no particles that could scracht the finish. Ensure the lacquered surface is totally cold (maximum 20ºC) before the cleaning.

Steel wool, abrasive cleaners, souring products as well as strong acids (hydrochloric and perchloric),strong bases (caustic soda or ammonia) or carbonated solutions are not recommended. Citric acid is neither recommended because disolves the protective layer of the surface of aluminium. Waxes, petrolatum, lanolin or similar substances are not appropriate. Solvents containing haloalkanes (hydrofluoroether and chlorinated solvents) and curing accelerators containing chlorides should not be used (use special accelerators free of chlorides).